Let me walk you through something that every welder—beginner or expert—needs to understand really well: the undercut defect in welding. I’ve seen this come up many times in workshops, on job sites, and even during inspections.

At first glance, it may not look like a big deal, but trust me, undercut can compromise the entire integrity of a weld.

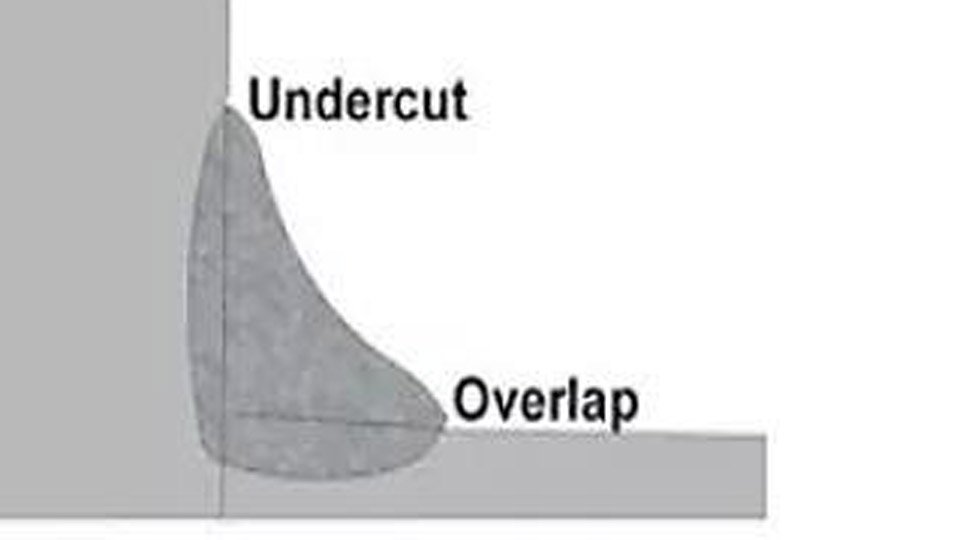

Image by researchgate

I’ll explain everything about undercut defects in welding—from what it is, why it happens, how to prevent it, and how to fix it.

If you’re welding thin metal sheets or thick structural steel, understanding this defect is a must if you want strong, clean, and safe welds.

I’ll keep the language simple and the concepts clear because welding is something everyone can learn, but only a few perfect. So, let’s get into it.

What an Undercut Is in Welding

An undercut in welding is a groove or notch that forms along the edge of the weld. Instead of the base metal smoothly blending into the weld bead, there’s a dip or a cut—almost like someone scooped out a bit of the parent metal along the weld toe.

You’ll often see it near the edges where the weld metal meets the base metal. It looks like a tiny valley, and even though it may seem small, it weakens the weld.

The reason this defect is a problem is because it creates a stress riser. That means if the metal is under load, vibration, or even weather conditions, cracks can start from this undercut and spread quickly. That’s not just a cosmetic flaw—it’s a safety issue.

What Causes an Undercut in Welding?

The root cause of an undercut is usually poor technique. I say that as someone who’s made that mistake early in my welding days. But don’t worry—once you know what to look out for, you can avoid it.

Here are the most common causes:

High Welding Current: When the current is too high, it melts the base metal excessively. The molten pool becomes too fluid and drains away before it solidifies, leaving a groove at the edge.

Incorrect Travel Speed: If you move the torch too fast, the metal doesn’t get enough time to fill the edges properly, and you’re left with a cut-like defect.

Wrong Electrode Angle: Holding the electrode at a steep angle or inconsistent position creates uneven heat and poor fusion, especially at the weld toe.

Poor Technique with Weaving or Stringer Beads: If you’re weaving too quickly or inconsistently, the filler metal won’t properly cover the edges.

Lack of Filler Metal: In some processes like TIG, if you don’t add enough filler rod while welding, the arc alone can cause undercut.

Understanding these causes is the first step toward eliminating the problem before it even starts.

Different Types of Undercut Defects

Not all undercuts are the same. Sometimes, it’s a deep notch. Other times, it’s a subtle groove that might not even be visible unless you inspect closely.

Here are the two main types:

- External Undercut: This appears on the outer surface of the weld, usually along the toe. It’s the most common type and also the most visible.

- Internal Undercut: Found on the root side of the weld, especially in double-sided welds or pipe welds. These can be tricky because they’re hidden unless you inspect them with X-rays or other testing methods.

Where Does It Usually Occur?

Undercuts tend to form:

- On the upper edges of horizontal welds

- At the toe of a fillet weld

- On pipe joints, especially in root passes

- Along vertical or overhead welds where control is more difficult

Knowing where it’s likely to occur helps you focus better while welding in those areas.

Why Is Undercut a Big Problem?

Now you might ask, “If it’s just a small groove, why worry so much?”

Here’s why:

It Weakens the Joint: The metal at the weld toe becomes thinner, and under load, this is where cracks can start.

Fatigue Cracks Develop Faster: In structures that experience vibration or repetitive stress, undercuts act as starting points for fatigue cracks.

It Can Cause Weld Failure: Over time, especially under extreme conditions, an undercut can grow into a larger crack, eventually leading to complete failure.

Inspection Failures: Most welding codes and inspection standards don’t allow visible undercut beyond certain limits. If you’re in construction, aerospace, pipelines, or shipbuilding, this could mean rework—or rejection.

How to Prevent Undercut in Welding

Good news? Undercut is very preventable.

Let me share some things I’ve learned over the years that really helped me get cleaner welds:

Control Your Welding Current

Always match your current with the electrode and base metal thickness. Too high, and you’ll burn away the edges. For example:

| Electrode Size | Base Metal Thickness | Recommended Amperage |

|---|---|---|

| 3/32” (2.4 mm) | 1/8” (3.2 mm) | 90–110 Amps |

| 1/8” (3.2 mm) | 1/4” (6.4 mm) | 120–150 Amps |

| 5/32” (4 mm) | 3/8”+ (9.5 mm) | 150–200 Amps |

Adjust depending on position (overhead may require less).

Maintain a Proper Travel Speed

Don’t rush the weld. Move steadily so that the molten pool has time to fill in the edges. Too fast, and you’ll get undercut. Too slow, and you’ll get a big buildup or burn-through.

Correct Electrode Angle

Keep the electrode angle consistent. For flat welds, a 10–15° drag angle works well. For vertical or overhead, be even more careful with the angle to avoid overheating the sides.

Use Proper Weaving Techniques

If you’re weaving, don’t make the pattern too wide. Stay within 2.5 times the electrode diameter. This keeps the weld focused and helps deposit metal evenly at the toes.

Choose the Right Filler Metal

Make sure the filler metal matches the job. Some materials flow better and wet the edges more effectively, reducing chances of undercut.

Improve Joint Fit-Up and Cleaning

If the edges of the base metal aren’t properly cleaned or beveled, filler metal might not flow correctly. Dirty metal can also cause arc instability.

How to Detect an Undercut Defect

Sometimes undercut is visible, sometimes it’s not. Here’s how you can check for it:

- Visual Inspection: Just look along the weld toes. A flashlight helps catch shadows in the groove.

- Weld Gauges: Use a weld undercut gauge. It measures the depth of the groove. Many codes specify that undercuts should not exceed 0.5 mm or so.

- Nondestructive Testing (NDT): For internal undercuts, use ultrasonic or radiographic testing. These are especially common in critical welds.

Repairing Undercut in Welds

So, what if you do find undercut? Should you panic? Nope.

Here’s how you fix it:

- Small Undercuts: If they’re shallow (within the allowed limit), they might be acceptable or could be ground and blended.

- Deep Undercuts: You’ll need to grind the area to clean it, and then re-weld. Make sure to use proper technique the second time to avoid repeat defects.

- After Re-welding: Always re-inspect. Don’t assume it’s fixed until you’ve checked it.

Undercut Limits in Welding Codes

Different codes allow different maximum undercut depths.

For example:

| Welding Code/Standard | Maximum Allowable Undercut |

|---|---|

| AWS D1.1 (Steel) | 1/32” (0.8 mm) |

| ASME Section IX | 1/64” (0.4 mm) typical |

| ISO Standards | Varies (typically 0.5 mm) |

Always check the project specs and follow them.

Personal Tips to Avoid Undercut

Over time, I’ve picked up a few things that helped me reduce undercuts almost completely:

- Practice on scrap metal first before jumping to actual work.

- Always do a test run when changing machines or settings.

- Take breaks during long welds to avoid fatigue—shaky hands can cause angle errors.

- Use proper lighting to see the weld toes clearly.

Conclusion

So, to wrap it all up, undercut is a common but avoidable defect in welding. It looks like a small groove, but it can lead to big problems if not addressed.

It weakens the weld, can lead to cracking, and often fails inspections. But with a good technique, proper settings, and a bit of patience, you can prevent it every time.

I’ve made my share of mistakes with undercuts, but once I learned the causes and how to control them, my welds got stronger, cleaner, and passed inspections without issues. I hope this helps you do the same.

If you’re just starting out or you’re refining your technique, keep practicing. Mastering the basics like avoiding undercut sets you apart from an average welder to a great one.

FAQs

What does an undercut look like in a weld?

It looks like a small groove or notch at the toe of the weld, where the base metal has been melted away slightly but not filled with weld metal.

Is undercut in welding dangerous?

Yes, it can be. It weakens the joint and can cause cracks over time, especially in structures that deal with stress or vibration.

Can you fix an undercut after welding?

Absolutely. You can grind the area to clean it up and re-weld to fill the groove properly.

How deep is too deep for an undercut?

According to AWS D1.1, an undercut should not exceed 1/32” (0.8 mm). Anything deeper may require repair.

What causes undercut when MIG welding?

It’s usually caused by using too high a current, traveling too fast, or having a poor torch angle. Keeping the right settings and speed helps prevent it.

Does undercut affect the strength of the weld?

Yes, it reduces the effective thickness of the base metal and creates points where cracks can begin, weakening the whole joint.

Is undercut allowed in welding inspection?

Some codes allow minor undercut within specific limits, but excessive undercut will lead to rejection in most inspections.