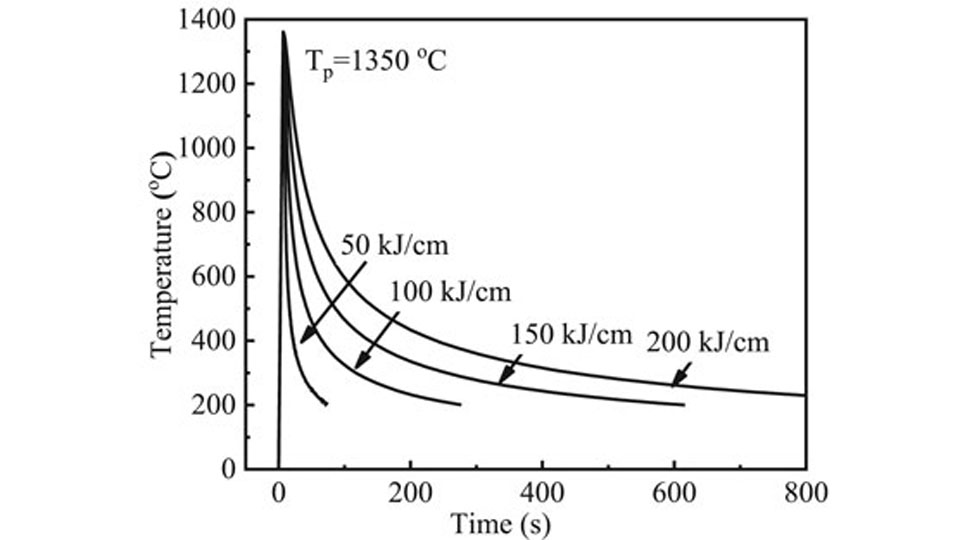

Heat input is one of the most important factors in welding. It determines how much energy is transferred from the welding arc to the base metal, affecting penetration, weld strength, and potential distortion. But when we talk about maximum heat input, we’re really asking—how much heat is too much?

Photos by frontiersin

I’ve worked on projects where managing heat input was critical, especially with high-strength steel and thin materials. Using too much heat can lead to warping, burn-through, or even metallurgical defects. On the other hand, certain materials, like thick structural steel, require higher heat input to ensure proper fusion.

In this guide, I’ll walk you through what maximum heat input means, how it’s calculated, and how to control it for better welding results.

Heat Input in Welding

Heat input refers to the amount of thermal energy applied to the workpiece per unit length of the weld. It directly affects weld quality, penetration depth, and the heat-affected zone (HAZ).

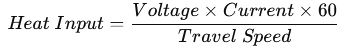

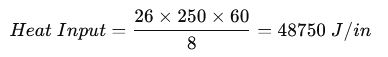

We use this formula to calculate heat input:

- Voltage (V): Electrical potential of the arc.

- Current (A): Amperage of the welding machine.

- Travel Speed (S): Speed of the welding process (inches per minute).

For example, if we use 26V, 250A, and a travel speed of 8 inches per minute, the heat input calculation looks like this:

This number tells us how much heat is being applied per inch of weld. But how much is too much?

What Determines Maximum Heat Input?

There is no single universal maximum heat input for welding because it depends on material type, thickness, and welding process. However, some key factors set the upper limit:

Base Metal Type and Thickness

- Thicker metals can handle higher heat input because they dissipate heat more effectively.

- Thin metals are more sensitive and can warp or burn through with excessive heat.

- High-strength and alloy steels often have strict heat input limits to maintain their mechanical properties.

Welding Process

Different welding processes have different maximum heat input thresholds.

| Welding Process | Typical Heat Input Range (J/in) |

|---|---|

| Stick Welding (SMAW) | 20,000 – 50,000 |

| MIG Welding (GMAW) | 10,000 – 40,000 |

| TIG Welding (GTAW) | 5,000 – 20,000 |

| Submerged Arc Welding (SAW) | 40,000 – 150,000 |

| Flux-Cored Arc Welding (FCAW) | 15,000 – 60,000 |

Processes like SAW can handle very high heat input without problems, while TIG welding is more delicate and works best with low heat input.

Metallurgical Considerations

Every metal has a heat tolerance beyond which its properties can degrade. If you exceed the recommended heat input, you can create:

- Excessive grain growth, weakening the metal.

- Reduced toughness, leading to cracks.

- Increased distortion, making alignment difficult.

This is why welding codes, such as AWS D1.1 for structural steel, specify heat input limits to preserve mechanical strength.

What Is the Maximum Heat Input in Welding?

The maximum allowable heat input depends on the welding procedure specifications (WPS) for the material and process being used. Here are some general guidelines:

- Structural Steel (A36, A572, etc.) → 50,000 – 80,000 J/in

- Stainless Steel (304, 316, etc.) → 30,000 – 50,000 J/in

- Aluminum Alloys → 10,000 – 30,000 J/in

- High-Strength Low Alloy (HSLA) Steels → 20,000 – 40,000 J/in

Many engineering codes specify maximum heat input values based on charpy impact testing and material toughness requirements. If you’re welding for structural applications, aerospace, or pipelines, following these limits is crucial.

How to Control Heat Input and Avoid Exceeding the Maximum

Now that we understand the risks of excessive heat input, let’s explore ways to control and manage it effectively.

Adjust Voltage and Amperage

- Lowering voltage and amperage reduces heat input.

- Using pulsed welding helps maintain penetration while keeping heat under control.

- Always match settings to the material thickness and joint configuration.

Increase Travel Speed

- Faster travel speed = lower heat input.

- Moving too slowly increases heat buildup and can exceed the maximum limit.

- Use automation for precise control when welding long sections.

Use Intermittent or Skip Welding

- Instead of a continuous weld, use shorter weld segments to prevent excessive heat buildup.

- Skip welding (welding in different locations instead of a straight pass) helps spread heat evenly.

Choose the Right Welding Process

- If heat input is a concern, TIG welding or pulsed MIG can reduce excess heat.

- SAW and FCAW produce high heat input but can be controlled with settings.

Use Preheat and Post-Weld Heat Treatment Wisely

- Preheating reduces thermal shock but increases overall heat input.

- Post-weld heat treatment (PWHT) relieves stress but must be carefully controlled to avoid excess heat exposure.

Signs You’re Exceeding Maximum Heat Input

If you’re worried about too much heat, watch for these signs:

- Excessive warping or distortion

- Weld undercut or burn-through

- Large heat-affected zone (HAZ)

- Brittle welds that crack easily

- Poor mechanical properties after testing

Conclusion

The maximum heat input in welding depends on the welding process, material type, and engineering requirements. Exceeding this limit can lead to weak welds, warping, and metallurgical defects.

To stay within safe limits:

- Adjust voltage, amperage, and travel speed

- Use pulsed or intermittent welding

- Follow WPS guidelines for your material

- Watch for signs of overheating and adjust accordingly

If you’re welding high-strength steel, stainless steel, or thin materials, controlling heat input is critical to ensuring weld quality.

By following these tips, you can avoid excessive heat buildup and produce strong, durable welds every time.

FAQs

What happens if heat input is too high in welding?

Excessive heat input can cause warping, excessive grain growth, poor toughness, and cracking in the weld or base metal.

What is the ideal heat input for welding?

It depends on the material and welding process. For example, TIG welding may require 5,000 – 20,000 J/in, while SAW can handle up to 150,000 J/in.

How can I reduce heat input in welding?

Increase travel speed, use lower voltage and amperage, switch to pulsed welding, and apply skip or intermittent welding techniques.

Does higher amperage mean more heat input?

Yes. Higher amperage increases heat input, which is why setting the correct current is important for weld quality.