When I first started welding, one of the most frustrating things I noticed was those tiny molten metal droplets flying everywhere. They would stick to my workpiece, my welding table, and even my protective gear.

It wasn’t just annoying—it made my welds look rough and required extra cleanup. If you’ve experienced the same thing, you know exactly what I’m talking about.

Image by fsmdirect

This unwanted mess is called welding spatter. It’s a common issue, but the good news is that it’s preventable.

Understanding what spatter is, why it happens, and how to reduce it can save you time, effort, and even money on cleanup and repairs.

Let’s go over everything you need to know about welding spatter and how to deal with it effectively.

Understanding the Welding Spatter

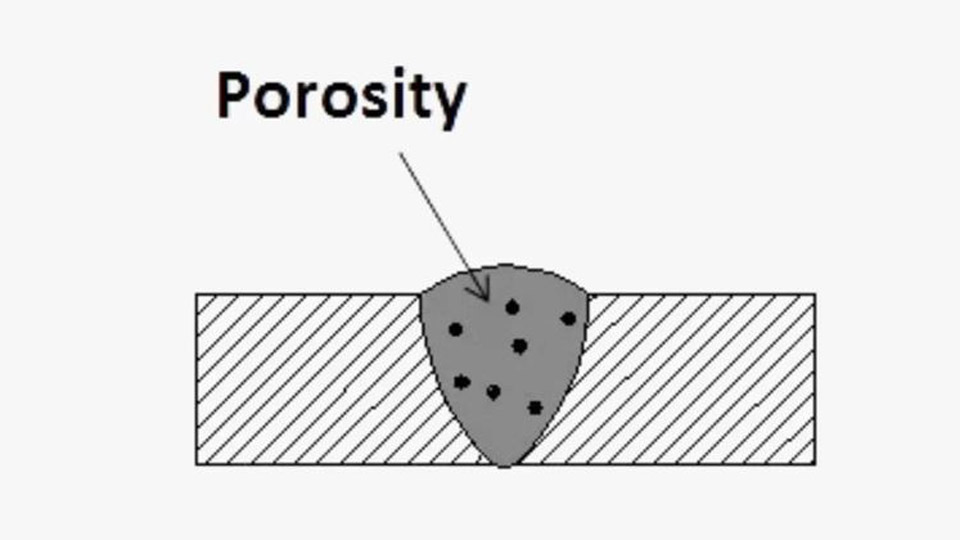

Welding spatter consists of small molten metal droplets that are expelled from the weld during the welding process.

These droplets cool and harden on surrounding surfaces, making cleanup a hassle. It’s most commonly seen in MIG (GMAW) and flux-cored (FCAW) welding, though it can occur in other welding processes as well.

While some amount of spatter is normal, excessive spatter is usually a sign that something is off in your welding setup or technique. The more you know about what’s causing it, the easier it is to fix.

Causes of Welding Spatter

Spatter happens when the molten metal from the arc doesn’t stay within the weld pool. Instead, it gets ejected and lands on surrounding surfaces. Here are some of the most common causes:

- Incorrect Voltage and Amperage Settings – Too much or too little voltage can create an unstable arc, leading to excess spatter.

- High Wire Feed Speed – If too much filler metal is being fed into the weld, it can cause spatter.

- Poor Shielding Gas Coverage – Inconsistent gas flow can create turbulence, which disturbs the arc and increases spatter.

- Contaminated Workpiece – Dirt, rust, oil, and paint on the base metal can cause an unstable arc and excess spatter.

- Wrong Polarity – Using the incorrect polarity setting on your welder can lead to excessive spatter.

- Bad Welding Technique – If the torch angle or travel speed is incorrect, spatter levels can increase.

Types of Welding Spatter

Not all spatter is the same. Understanding the different types can help you diagnose and fix the issue.

| Type of Spatter | Description | Common Cause |

|---|---|---|

| Fine Droplet Spatter | Small, tiny metal droplets spread around the weld area. | High wire feed speed or improper voltage. |

| Large Droplet Spatter | Bigger metal globs that stick to surfaces. | Unstable arc, contamination, or bad gas coverage. |

| Arc Blow Spatter | Spatter caused by magnetic disturbances in DC welding. | Poor grounding or magnetic field interference. |

Effects of Welding Spatter

If left unchecked, welding spatter can cause a number of problems, including:

- Messy and Unprofessional Welds – Spatter makes the final weld look rough and unattractive.

- Extra Cleanup Time – Removing hardened spatter adds time and effort to your project.

- Equipment Damage – Spatter can stick to your welding nozzle, clogging it and reducing performance.

- Weaker Welds – Too much spatter can indicate an unstable arc, leading to weak or porous welds.

How to Reduce Welding Spatter

Spatter is frustrating, but it’s not something you have to accept as part of the job. With the right techniques, you can greatly reduce the amount of spatter in your welding process.

Adjust Voltage and Amperage

One of the biggest causes of spatter is incorrect machine settings. If your voltage is too low, the arc becomes unstable. Too high, and you’ll end up with excessive heat and spatter.

How to fix it:

- Start with the recommended settings for your wire size and material thickness.

- Adjust voltage and amperage in small increments to find the balance that produces a smooth, stable arc.

Control Your Wire Feed Speed

A fast wire feed speed can push too much filler material into the weld, causing excessive spatter. If it’s too slow, the arc will be inconsistent.

How to fix it:

- Set the wire feed speed according to your welder’s recommendations.

- If you notice spatter, try slightly reducing the speed until the arc stabilizes.

Use the Right Shielding Gas

Shielding gas plays a crucial role in keeping the weld pool stable. If gas coverage is poor, the arc becomes unstable, leading to spatter.

Best practices:

- For MIG welding on mild steel, use 75% argon / 25% CO₂ for cleaner welds.

- Avoid using pure CO₂, as it increases spatter.

- Set the gas flow rate between 20-25 CFH (cubic feet per hour) for proper coverage.

Keep Your Workpiece Clean

Contaminants like rust, grease, and dirt interfere with the welding process, increasing spatter.

How to fix it:

- Clean the metal surface using a wire brush, grinder, or degreaser before welding.

- Remove paint and coatings before starting.

Maintain Proper Welding Technique

Even with the right settings, poor welding technique can still lead to spatter.

Key things to focus on:

- Keep a steady hand to maintain arc stability.

- Hold the torch at a 10-15° angle for MIG welding.

- Use a consistent travel speed—not too fast, not too slow.

Use Anti-Spatter Spray

If spatter is still a problem, you can apply an anti-spatter spray to your workpiece and equipment. This creates a protective coating that prevents spatter from sticking.

- Spray a light coating on the work area and welding nozzle before welding.

- Wipe off excess spray to avoid contamination.

- Use silicone-free sprays if you plan to paint the weld afterward.

How to Remove Welding Spatter

Even if you take every precaution, you may still get some spatter. Here are a few ways to remove it:

- Chipping Hammer – Good for knocking off larger spatter deposits.

- Wire Brush – Works well for light spatter on surfaces.

- Grinder – Best for heavy spatter buildup that won’t come off easily.

- Anti-Spatter Gel for Nozzles – Helps prevent buildup inside your welding torch.

Conclusion

Welding spatter is something every welder deals with at some point, but it doesn’t have to be a major problem. With proper machine settings, good technique, and a clean work surface, you can significantly reduce the amount of spatter in your welds.

If you’re struggling with excessive spatter, start by checking your voltage, wire speed, and gas flow. Keep your workpiece clean, use the right polarity, and hold the torch at the correct angle. Small adjustments can make a big difference.

At the end of the day, welding is all about practice and learning from experience. The more you weld, the better you’ll get at controlling spatter and creating smooth, clean welds.

FAQs

What is welding spatter?

Welding spatter refers to small droplets of molten metal that are expelled from the weld and land on surrounding surfaces.

Why does my weld have so much spatter?

Spatter is usually caused by incorrect voltage, high wire feed speed, poor shielding gas coverage, or a contaminated workpiece.

Can I prevent welding spatter completely?

While some spatter is unavoidable, using the right settings and technique can significantly reduce it.

Does gas type affect welding spatter?

Yes, a 75% Argon / 25% CO₂ mix produces less spatter than pure CO₂.

How do I clean up welding spatter?

You can remove spatter with a chipping hammer, wire brush, grinder, or anti-spatter spray.