Welding is one of the most important skills in metalworking, and there are many different techniques used depending on the type of metal, the thickness, and the desired strength of the weld.

I’ve worked with a variety of welding methods, each with its own advantages and challenges. Some are great for precision work, while others are better for heavy-duty construction or repairs.

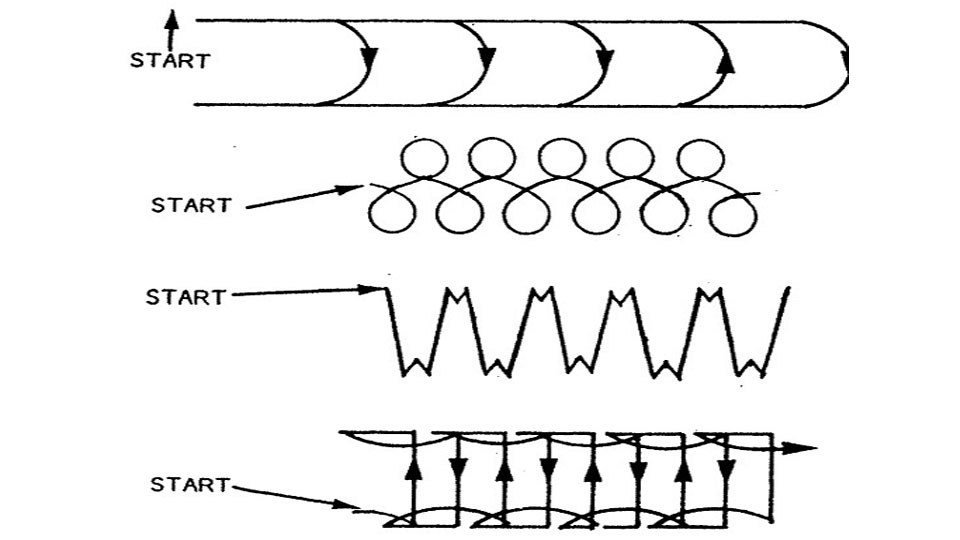

Image by wcwelding

If you’re looking to learn about the different welding techniques, whether you’re a beginner or an experienced welder, it’s important to understand how each method works, what it’s best used for, and how to choose the right one for your project.

Let’s go through the major welding techniques and explore their uses, advantages, and limitations.

Shielded Metal Arc Welding (SMAW) – Stick Welding

Stick welding, or shielded metal arc welding (SMAW), is one of the oldest and most commonly used welding techniques. It involves using a flux-coated electrode, which creates a protective gas shield around the weld as it melts.

This method is great for outdoor work because it doesn’t require a shielding gas tank. It’s also highly versatile and can be used on rusty or dirty metal. However, it produces a lot of slag and requires regular cleaning between welds.

Best Uses:

- Structural welding

- Pipeline construction

- Heavy equipment repairs

- Farm and outdoor welding

Pros:

- Works well in windy or outdoor conditions

- Inexpensive and portable

- Good for thick metals

Cons:

- Produces a lot of slag

- Requires frequent rod changes

- Can be harder to learn for beginners

Gas Metal Arc Welding (GMAW) – MIG Welding

MIG welding, or gas metal arc welding (GMAW), is one of the easiest and most commonly used welding techniques, especially for beginners. It uses a continuously fed wire electrode and a shielding gas, which helps produce clean, strong welds with minimal slag.

One of the biggest advantages of MIG welding is its speed. It allows for continuous welding without stopping to change rods like in stick welding. However, it requires a shielding gas, which makes it less effective outdoors in windy conditions.

Best Uses:

- Automotive repair

- Fabrication and manufacturing

- Home and hobby welding

- Thin metal welding

Pros:

- Easy to learn

- Fast and efficient

- Produces clean welds with minimal slag

Cons:

- Not ideal for outdoor use

- Requires a shielding gas

- Less effective on very thick metal

Gas Tungsten Arc Welding (GTAW) – TIG Welding

TIG welding, or gas tungsten arc welding (GTAW), is known for its precision and high-quality welds. It uses a tungsten electrode and a separate filler rod, along with a shielding gas like argon to protect the weld.

TIG welding takes more skill to master because it requires using both hands – one for the torch and the other for the filler rod. However, the control it offers makes it the best choice for fine, detailed work and thin metals.

Best Uses:

- Aerospace and aircraft welding

- Custom fabrication

- Stainless steel and aluminum welding

- Precision and artistic welding

Pros:

- Produces the highest-quality welds

- Works well on thin metals

- No slag, making cleanup easier

Cons:

- Slower than MIG and stick welding

- Requires more skill and control

- Not ideal for thick metals or outdoor use

Flux-Cored Arc Welding (FCAW)

Flux-cored arc welding (FCAW) is similar to MIG welding, but it uses a special tubular wire filled with flux instead of a solid wire. This allows it to work without an external shielding gas, making it great for outdoor welding in windy conditions.

It’s often used in heavy-duty applications like shipbuilding, construction, and industrial fabrication because it allows for deep penetration and strong welds. However, it can produce a lot of spatter and requires cleanup.

Best Uses:

- Construction and heavy fabrication

- Outdoor welding in windy conditions

- Shipbuilding and industrial applications

Pros:

- Doesn’t always require shielding gas

- Good penetration for thick metals

- Works well in outdoor conditions

Cons:

- Produces more spatter than MIG welding

- Can be messier than other methods

- Requires specialized wire

Oxy-Acetylene Welding (Gas Welding)

Oxy-acetylene welding is an older welding technique that uses a combination of oxygen and acetylene gases to create a flame hot enough to melt metal. It’s not as common today for structural welding but is still used for brazing, soldering, and cutting metal.

This method gives a lot of control over heat input, making it great for thin metals. It’s often used in jewelry making, automotive repairs, and art metalwork.

Best Uses:

- Sheet metal fabrication

- Brazing and soldering

- Artistic metalworking

- Small repairs and cutting

Pros:

- Good for thin metals

- Portable and versatile

- Can also be used for metal cutting

Cons:

- Not ideal for structural welding

- Slower than arc welding methods

- Requires gas tanks and careful handling

Plasma Arc Welding (PAW)

Plasma arc welding is similar to TIG welding but uses a focused plasma arc for more precision. It produces high-quality, deep-penetration welds and is often used in aerospace and high-tech applications.

It requires expensive equipment and is mostly used in specialized industries rather than general welding applications.

Best Uses:

- Aerospace and precision welding

- High-quality industrial applications

- Automated welding processes

Pros:

- Very precise and clean welds

- Works on a wide range of metals

- Can weld at high speeds

Cons:

- Expensive and complex equipment

- Not commonly used outside of specialized industries

Submerged Arc Welding (SAW)

Submerged arc welding is an automated process where the arc is completely covered by a granular flux, preventing spatter and contamination. It’s mainly used in industrial applications where high-speed, large-scale welding is needed.

Since it requires special machinery, it’s not something you’ll see in everyday welding shops, but it’s widely used in shipbuilding, pipelines, and structural fabrication.

Best Uses:

- Heavy industrial welding

- Large-scale manufacturing

- Shipbuilding and pipeline construction

Pros:

- High-speed welding

- Minimal spatter and contamination

- Strong, high-quality welds

Cons:

- Requires special equipment

- Limited to flat or horizontal welding

Choosing the Right Welding Technique

Different welding techniques are suited for different applications. Here’s a quick comparison to help you decide:

| Welding Technique | Best For | Skill Level | Outdoor Use? | Speed | Cost |

|---|---|---|---|---|---|

| Stick Welding (SMAW) | Structural, outdoor repairs | Medium | Yes | Medium | Low |

| MIG Welding (GMAW) | Automotive, fabrication | Easy | No | Fast | Medium |

| TIG Welding (GTAW) | Precision, artistic work | Hard | No | Slow | High |

| Flux-Cored (FCAW) | Heavy-duty, outdoor work | Medium | Yes | Fast | Medium |

| Oxy-Acetylene | Thin metals, brazing | Medium | Yes | Slow | Medium |

| Plasma Arc Welding | Aerospace, high-tech | Hard | No | Fast | High |

| Submerged Arc Welding | Industrial, shipbuilding | Hard | No | Very Fast | High |

Conclusion

There’s no one-size-fits-all when it comes to welding techniques. It really depends on what you’re working on, the materials, and the conditions. If you’re just starting, MIG welding is the easiest to learn, while TIG welding gives the best control for high-quality welds. Stick welding is great for rough outdoor jobs, and flux-cored welding is a solid choice for industrial work.

Whatever method you choose, the key to great welding is practice, patience, and knowing how to adjust your settings for different metals.

Frequently Asked Questions (FAQs)

What is the easiest welding technique for beginners?

MIG welding is the easiest to learn because it uses a simple wire feed system and produces clean welds.

Which welding technique is the strongest?

TIG welding and stick welding produce the strongest welds when done correctly.

Can I weld without gas?

Yes, stick welding and flux-cored welding don’t require external shielding gas.

What is the best welding method for aluminum?

TIG welding is the best choice for aluminum because it provides precise control and clean welds.