If you’re getting into welding, you’ve probably heard about TIG welding and plasma welding. Both of these methods offer precision, quality, and versatility, making them popular for professional welders and hobbyists alike. But when it comes down to choosing the right process, it’s important to understand their differences.

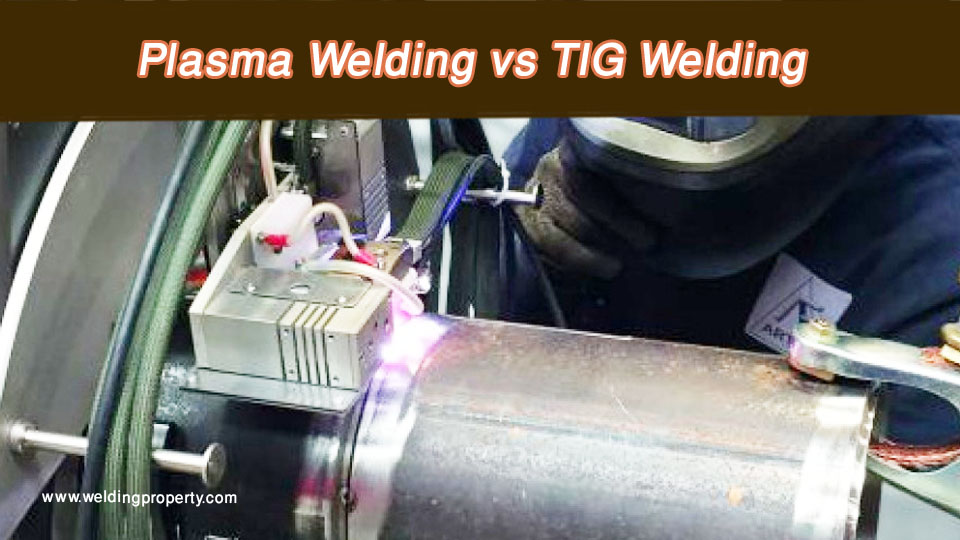

Image by home-of-welding

I’ve spent a good amount of time working with both TIG and plasma welding, and I know firsthand how each method has its strengths and weaknesses. If you’re wondering which one is better for your specific needs, I’m here to break it all down for you in the simplest way possible.

By the time we’re done, you’ll have a clear idea of how these two welding processes compare, when to use them, and which one suits your projects best.

What Is TIG Welding?

TIG (Tungsten Inert Gas) welding, also known as Gas Tungsten Arc Welding (GTAW), is a precise and clean welding process that uses a non-consumable tungsten electrode to create the weld. It requires an external shielding gas, usually argon, to protect the weld from contamination.

This method is well-known for producing high-quality, clean welds, making it ideal for applications where appearance and strength matter. TIG welding is commonly used in industries such as aerospace, automotive, and fabrication of stainless steel and aluminum structures.

One of the best things about TIG welding is the control it gives you. You have full command over the heat, the weld pool, and the amount of filler material added (if needed). It’s a skill that takes time to master, requiring a steady hand and patience.

What Is Plasma Welding?

Plasma Arc Welding (PAW) is similar to TIG welding but uses a more advanced approach. Instead of relying on a free-flowing arc like TIG, plasma welding constricts the arc through a small orifice, creating a high-energy plasma stream.

This concentrated plasma arc can reach much higher temperatures and offers deeper penetration, making it ideal for precise, automated welding applications. It is commonly used in aerospace, medical device manufacturing, and other industries that require intricate welds with minimal distortion.

Plasma welding also uses a shielding gas, but it has an additional plasma gas, which helps control the arc and enhances performance. This makes the process more stable and efficient, especially for welding thicker materials.

Differences Between Plasma Welding and TIG Welding

Now that you have a basic idea of what each process is, let’s compare them side by side.

Arc Formation and Stability

- TIG Welding: Uses an open arc between the tungsten electrode and the workpiece. The arc is stable but can be affected by external factors like wind or shielding gas inconsistencies.

- Plasma Welding: Uses a constricted arc, which increases energy density and stability. The arc is more focused and less affected by external factors.

Heat and Penetration

- TIG Welding: Produces a softer arc with moderate penetration, making it great for thin materials and precision welding.

- Plasma Welding: Generates a much hotter arc with deeper penetration, allowing it to handle thicker materials more efficiently.

Speed and Efficiency

- TIG Welding: Slower compared to plasma welding, as it requires precise control of the weld pool and filler material.

- Plasma Welding: Faster, especially for automated applications. The concentrated arc allows for quicker welding speeds with minimal distortion.

Ease of Use and Learning Curve

- TIG Welding: Has a steep learning curve, as it requires manual dexterity and precise control. Ideal for experienced welders.

- Plasma Welding: More technical but often automated, making it easier to use in industrial settings. However, setting up and maintaining the equipment requires expertise.

Shielding Gas and Equipment Complexity

- TIG Welding: Uses argon or helium as shielding gas and requires a relatively simple setup.

- Plasma Welding: Uses both shielding and plasma gas, requiring more complex equipment and additional components like a plasma torch.

Cost of Equipment and Operation

- TIG Welding: More affordable to set up, with lower initial investment costs. Consumables are readily available and cost-effective.

- Plasma Welding: Higher initial costs due to the advanced equipment required, but offers efficiency and durability in high-production environments.

Applications and Suitability

- TIG Welding: Best for thin materials, intricate designs, and applications where weld aesthetics matter. Common in aerospace, automotive, and artistic metalwork.

- Plasma Welding: Ideal for industrial applications requiring deep penetration, high precision, and automated welding. Common in aerospace, shipbuilding, and medical device manufacturing.

Which One Should You Choose?

The choice between TIG and plasma welding depends on your specific needs.

- If you’re working on thin materials, custom fabrication, or artistic projects, TIG welding is the way to go. It gives you better control and produces visually appealing welds.

- If you need deep penetration, high-speed welding, or automated precision, plasma welding is the better option. It’s more suited for industrial applications where consistency and efficiency are key.

For hobbyists or small-scale welders, TIG welding is the more practical choice since it’s easier to access and more affordable. Plasma welding, on the other hand, is typically used in advanced manufacturing setups due to its high-tech requirements.

Conclusion

Both plasma welding and TIG welding have their own strengths and are valuable in different scenarios. If you need precision, control, and clean welds, TIG welding is your best bet. But if you’re dealing with high-volume production and need efficiency, plasma welding is the superior choice.

The best welding method depends on what you’re trying to achieve. Whether you’re a beginner learning the ropes or a professional welder looking to optimize your process, knowing the differences between these two methods will help you make an informed decision.

Frequently Asked Questions (FAQs)

What is the main difference between TIG and plasma welding?

TIG welding uses an open arc and a tungsten electrode, while plasma welding uses a constricted arc for higher energy density and deeper penetration.

Which one is better for beginners, TIG or plasma welding?

TIG welding is more accessible for beginners, though it still requires practice. Plasma welding is mostly used in industrial settings and requires technical expertise.

Is plasma welding more expensive than TIG welding?

Yes, plasma welding equipment is more expensive due to its advanced technology. TIG welding is more cost-effective for small shops and hobbyists.

Can I use TIG welding for thick materials?

Yes, but it may require multiple passes. Plasma welding is better suited for thick materials due to its deeper penetration.

Which welding process provides better-looking welds?

TIG welding generally produces cleaner and more visually appealing welds, making it popular for applications where aesthetics matter.

Does plasma welding require shielding gas?

Yes, plasma welding uses both shielding gas and plasma gas to maintain arc stability and protect the weld.

Is plasma welding faster than TIG welding?

Yes, plasma welding is much faster, especially when used in automated systems, making it ideal for high-production environments.

I hope this guide helps you understand the differences between TIG and plasma welding. If you have any more questions, feel free to ask! Happy welding!

![HITBOX Plasma Cutter Welder Combo, 4 IN 1 [Air Sensor Technology] 50Amp HF Non-Touch Pilot Arc TIG Welding with Foot Pedal, 110V/220V 2T/4T Stick/MMA/Pulse TIG, Whole LED Display Screen (CT-520)](https://m.media-amazon.com/images/I/41ka1SubGxL._SL160_.jpg)