You’re in the middle of welding a crucial joint, and suddenly, your MIG welder starts spewing wire like a runaway train. You let go of the trigger, but the wire keeps coming—jamming, birdnesting, or worse, ruining your workpiece.

Image by mig-welding.co.uk

I’ve been there, sweating over a spool of wire that seemed possessed. But after years of troubleshooting (and a few tantrums), I’ve learned that uncontrolled wire feeding is almost always fixable with a little know-how.

Let’s break down why your MIG welder won’t stop feeding wire and how to get back to welding smoothly.

Why Your MIG Welder Won’t Stop Feeding Wire

A MIG welder feeds wire when the trigger is pressed. If it’s feeding nonstop, something’s overriding that trigger signal. Here are the usual suspects:

- Stuck Trigger or Faulty Switch: The trigger isn’t releasing physically or electrically.

- Stuck Relay or Contactor: A welded relay keeps the circuit closed.

- Loose Connections or Shorts: Wires touching where they shouldn’t.

- Drive Roller Tension Too High: Forces wire through even when the trigger’s off.

I once spent hours blaming my welder, only to find a tiny metal shard lodged in the trigger. Facepalm moment!

Step 1: Check the Trigger Mechanism

Start here—it’s the simplest fix.

- Unplug the Welder: Safety first!

- Inspect the Trigger: Open the gun handle. Look for dirt, debris, or damage.

- Test Continuity: Use a multimeter. Press the trigger—it should show continuity. Release—it should stop.

- Clean or Replace: Spray contact cleaner or replace a stuck trigger.

Pro Tip: If your gun has a “lock” feature, make sure it’s disengaged. I’ve confused that for a malfunction before.

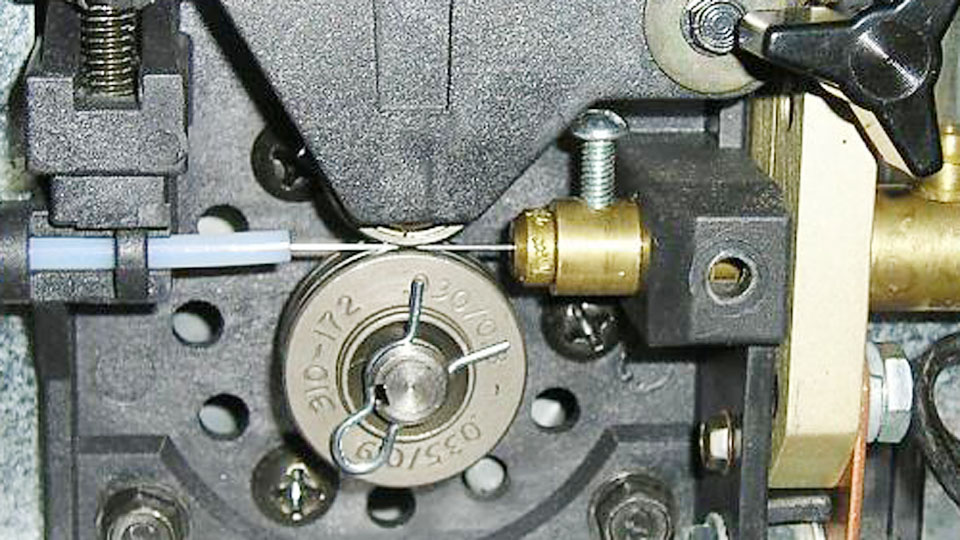

Step 2: Examine the Drive Roller System

If the trigger’s fine, the drive rollers might be forcing wire through. Here’s how to troubleshoot:

| Symptom | Likely Cause | Fix |

|---|---|---|

| Wire feeds after trigger release | Roller tension too tight | Loosen tension knob 1–2 clicks |

| Erratic feeding | Wrong roller groove | Match roller size to wire (0.030” wire = 0.030” groove) |

| Birdnesting | Worn drive rollers | Replace rollers |

Use a Sharpie to mark tension settings. Takes the guesswork out of adjustments.

Step 3: Inspect the Liner and Contact Tip

A kinked liner or clogged tip creates resistance, tricking the feeder into overcompensating.

- Remove the Contact Tip: Check for spatter or debris. Soak in vinegar if crusty.

- Check the Liner: Straighten it out. If bent, replace it—$10 fix vs. hours of frustration.

- Test Feed Manually: Disconnect the gun, push wire through by hand. It should glide smoothly.

I once fought a “haunted” feeder for days—turned out the liner was 3 inches too short.

Step 4: Test the Control Board and Relays

If mechanical parts check out, the issue might be electrical:

- Locate the Contactor/Relay: Usually near the power source.

- Listen for Clicks: When you press/release the trigger, the relay should click on/off.

- Check for Sticking: If the relay stays closed, tap it gently or replace it.

Warning: Messing with electronics voids warranties. If unsure, call a pro.

Step 5: Reset the Welder’s Settings

Sometimes, the welder just needs a reboot:

- Turn Off and Unplug: Wait 5 minutes.

- Check Voltage/Wire Speed: Reset to factory settings (see manual).

- Test on Scrap Metal: Gradually adjust settings.

My old welder had a quirky control board that glitched if settings were maxed out.

Preventive Maintenance to Avoid Future Jams

Stop problems before they start:

- Lube the Liner: Silicone spray every 6 months.

- Replace Consumables: Tips, nozzles, and liners wear out. Keep spares.

- Store Wire Properly: Keep spools dry to prevent rust-induced friction.

FAQs About Runaway MIG Welder Wire

Why does my wire keep feeding after I let go?

Stuck trigger, faulty relay, or excessive drive roller tension.

Can a bad ground cause wire feed issues?

Indirectly. Poor grounding creates erratic arcs, which may trick the feeder.

How tight should drive rollers be?

Tight enough to grip wire without crushing it. Test: Wire shouldn’t slip or flatten.

Why does my wire birdnest at the feeder?

Liner blockage, incorrect roller tension, or misaligned drive rolls.

Can I fix a stuck relay myself?

If you’re skilled with electronics. Otherwise, consult a technician.

Why does my wire feed inconsistently?

Worn rollers, kinked liner, or low voltage.

Should I oil my MIG welder’s wire feeder?

No! Oil attracts dust. Use dry lubricants like graphite spray.

Can cheap wire cause feeding issues?

Yes. Poorly wound or rusty wire jams feeders. Spend a few extra bucks on quality.

Why does my feeder motor hum but not turn?

Jammed wire or seized motor. Unplug and clear obstructions.

How often should I replace the liner?

Every 1–2 years for casual use, sooner for heavy-duty work.

Final Thoughts

A runaway MIG welder can turn a simple project into a nightmare. But with patience and systematic troubleshooting, you’ll diagnose 90% of issues in minutes.

Start simple, stay calm. Check the trigger, adjust the rollers, and work your way up. Soon, you’ll laugh at the days when a birdnest of wire felt like the end of the world.

Got a stubborn feeder or a success story? Drop a comment—I’m here to help you weld on!