When you’re working on welding projects, getting the fillet weld size right is one of the most important steps you can take for a strong and safe final product.

I’ve spent a lot of time working in different welding environments, and this question comes up more often than you might think: What is the maximum fillet weld size for plate thickness?

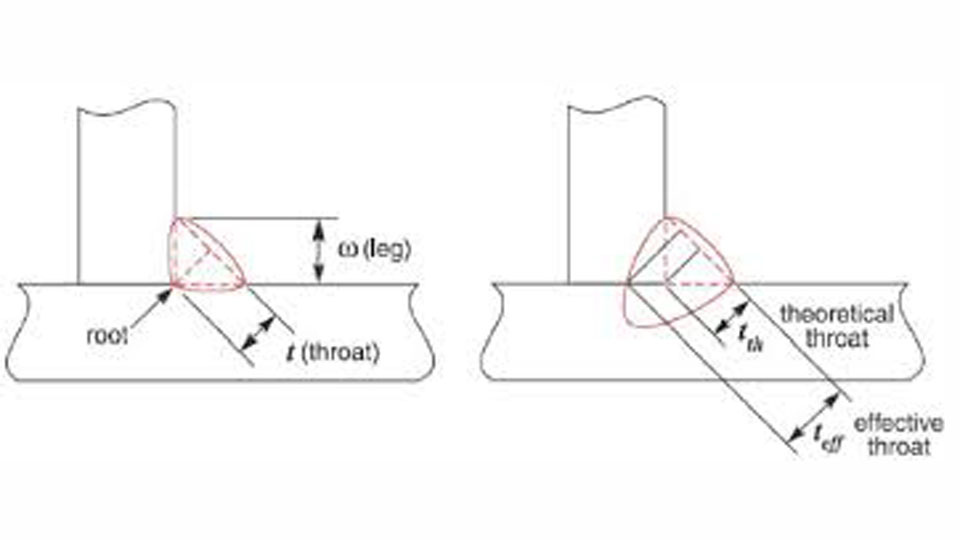

Photo by researchgate

Knowing this is not just about following a codebook. It’s about making sure your work holds up under pressure, stays safe, and lasts a long time.

If you’re welding structural steel, building custom frames, or just working on personal projects, understanding the relationship between plate thickness and fillet weld size is absolutely key.

I’ll walk you through everything you need to know about maximum fillet weld sizes. We’ll break it down into simple, clear explanations so that by the end of this, you’ll feel confident about how to size your fillet welds properly.

What Is a Fillet Weld?

A fillet weld is one of the most common types of welds you’ll see. It’s a triangular weld used to join two surfaces at a right angle — basically, where two metal pieces meet, like in a T-joint or corner joint.

It looks simple but plays a huge role in the strength and stability of structures. The size of that triangular weld matters a lot because it determines how much load it can carry without failing.

Why Does the Maximum Fillet Weld Size Matter?

You might think, bigger weld, stronger joint, right?

Well, not exactly.

If you make a fillet weld too large compared to the base metal’s thickness, it can actually cause problems:

- Excessive heat input can weaken the metal.

- Distortion can pull the pieces out of alignment.

- Overwelding wastes time, material, and money.

- Potential cracking can happen near the weld zone.

Good welding isn’t about piling up as much metal as possible. It’s about making the weld just the right size for the job — strong enough to hold but not so big that it causes other issues.

General Guidelines for Maximum Fillet Weld Size

Now, here’s what you really need to know.

According to general welding practices and codes (like AWS D1.1 Structural Welding Code — Steel), there are some commonly accepted guidelines for maximum fillet weld sizes:

For plates under 1/4 inch thick: The maximum fillet weld size should not be more than the thickness of the base metal.

For plates 1/4 inch thick and thicker: The maximum fillet weld size should generally not exceed the thickness of the thinner part being welded.

When welding to the edge of a plate (without end preparation): The maximum weld size should be no more than 1/16 inch less than the thickness of the plate.

Let’s organize that into a quick table for easier viewing:

| Plate Thickness | Maximum Fillet Weld Size |

|---|---|

| Less than 1/4 inch | Equal to plate thickness |

| 1/4 inch or greater | Equal to thinner part thickness |

| At edge (no prep) | 1/16 inch less than plate thickness |

It sounds complicated when reading, but once you get used to it, it becomes second nature.

How to Measure Fillet Weld Size

You might be wondering, how do I measure it accurately?

Well, we use something called a fillet weld gauge. This handy tool quickly checks the leg size of your welds. The “leg” of a fillet weld is the distance from the root of the joint out to the toe (outer edge) of the weld, measured along the surfaces.

In most cases, the size is based on the legs being equal. For example, a 1/4″ fillet weld would have two legs, each measuring 1/4″.

If you don’t have a gauge, you can use a ruler or calipers, but the fillet weld gauge really makes it quick and consistent.

Factors That Affect Maximum Fillet Weld Size

Several real-world factors can affect how big you can make your fillet welds. Let me walk you through a few important ones:

Type of Joint

The joint design plays a big role. For instance:

- T-joints can usually handle bigger fillet welds.

- Lap joints may require smaller fillet welds to avoid overheating the thinner plate.

- Corner joints can be tricky because they often involve welding on the edge of the plate.

Always think about the geometry and how much access you have for your electrode or torch.

Plate Thickness Difference

When welding two plates of different thicknesses, base your maximum weld size on the thinner plate, not the thicker one. You want the weld to penetrate well into both parts without overheating the thinner piece.

Welding Position

Position matters a lot too.

- In flat position, you can easily make larger welds because gravity helps you.

- In overhead or vertical welding, it’s much harder to control big welds, so sizes may be limited.

Welding Process Used

Different welding processes affect how much heat goes into the metal. Stick welding (SMAW), MIG (GMAW), TIG (GTAW), and Flux Core (FCAW) all behave a little differently. High heat input processes may require smaller fillet sizes to avoid excessive melting.

Special Situations: Minimum Fillet Weld Sizes

Sometimes people ask me about minimum weld sizes too — and that’s important because a weld that’s too small can fail under load.

As a rule of thumb:

- Minimum fillet weld size depends on the thickness of the thicker plate.

- For plates 1/4″ thick or less, the minimum size is typically around 1/8″.

- For thicker plates, the minimum gets a little larger.

But remember, today’s focus is on the maximum, so just know that the weld should always be big enough to handle the expected load but not so big that it causes issues.

Tips for Making the Perfect Fillet Weld Size

Let me give you some of the personal tips I’ve learned the hard way over the years:

- Fit-up is critical: Make sure your parts are aligned properly before welding. Poor fit-up makes it hard to control the fillet size.

- Use the right amperage: Too much heat will spread your puddle and oversize the weld.

- Practice consistency: Try to maintain a steady travel speed and arc length.

- Keep an eye on leg length: A small adjustment in angle can change the size of your weld dramatically.

Fillet Weld Size Chart for Common Plate Thicknesses

Here’s a simple example chart that you can use when you’re just starting out:

| Thinner Plate Thickness | Maximum Fillet Weld Size |

|---|---|

| 1/8″ (0.125″) | 1/8″ |

| 3/16″ (0.1875″) | 3/16″ |

| 1/4″ (0.25″) | 1/4″ |

| 3/8″ (0.375″) | 3/8″ |

| 1/2″ (0.5″) | 1/2″ |

This is a general guide. Always double-check if you’re following any project-specific codes or blueprints.

Common Mistakes to Avoid

If you’re learning about weld sizes, it’s good to know what mistakes can cost you time, material, and money.

- Overwelding: Wasting material and causing distortion.

- Ignoring thinner plate rule: Always base size on the thinner part.

- Poor inspection: Always use a gauge, even if you think your eye is good.

- Not adjusting for position: Overhead fillet welds can sag if too large.

- Misreading blueprints: Sometimes, the blueprint will specify a different weld size; always read carefully.

Practical Example: Welding a Frame for a Trailer

Let’s say you’re welding a trailer frame. You have 1/4″ thick steel plates. Based on what we’ve talked about:

- The maximum fillet weld size would be 1/4″.

- If you had a 1/4″ plate welded to a 3/16″ plate, the maximum size would be 3/16″ (because you go by the thinner piece).

Doing it this way makes sure your welds are not just strong, but also efficient and professional-looking.

Conclusion

Understanding the maximum fillet weld size for plate thickness isn’t just a technical requirement — it’s about doing solid, reliable work that lasts. When I started welding, I thought bigger was better. But experience quickly taught me that smart, properly sized welds are what real craftsmanship is all about.

By matching your weld size to your plate thickness, following good practices, and always measuring carefully, you’re setting yourself up for success. If you’re building structures, machinery, or art, good welding starts with good fundamentals like this.

Every great welder was once where you are now — curious, learning, and getting better with every bead they laid down. Stick with it, and you’ll see the difference in your work.

FAQs

What is the maximum fillet weld size for a 1/4″ thick plate?

The maximum fillet weld size for a 1/4″ thick plate is 1/4″, matching the thickness of the plate.

Should the fillet weld size match the thinner or thicker plate?

The fillet weld size should match the thickness of the thinner plate when welding two different thicknesses together.

Why shouldn’t I make fillet welds bigger than needed?

Making welds larger than necessary can cause overheating, distortion, material waste, and even weaken the surrounding metal.

What tool is used to measure fillet weld size?

A fillet weld gauge is commonly used to measure weld size accurately and quickly.

Can I make larger welds in flat position compared to overhead?

Yes, in flat position, you can make larger welds more easily because gravity helps the weld pool stay in place, unlike overhead welding.