When I first started working with cast iron, I quickly learned that repairing cracks without welding can be a real challenge. Cast iron is strong, but it’s also brittle.

When it cracks, it can be difficult to fix without making the damage worse. Welding isn’t always the best option because cast iron is sensitive to heat and can crack even more if not handled properly.

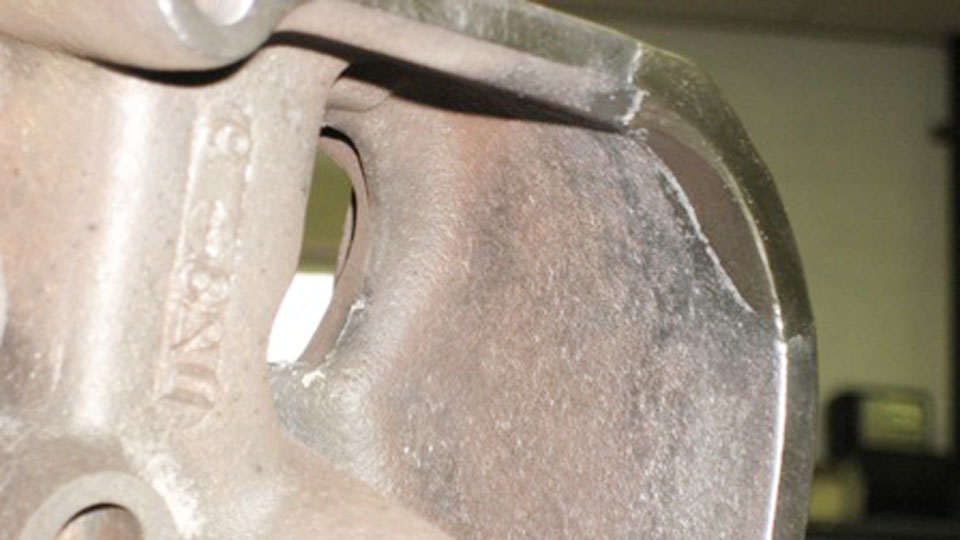

Image by rlengines

There are several effective ways to repair cast iron cracks without welding. If you’re working on an old engine block, a cast iron pan, or a machine part, there are techniques that can restore its strength without using a welder.

Let’s go through some of the best methods, step by step, so you can choose the one that works best for your situation.

Why Avoid Welding for Cast Iron Repairs?

Before we get into the repair methods, let’s talk about why welding isn’t always the best solution for cast iron.

- Cast iron is brittle and heat-sensitive – When heated unevenly, it can develop more cracks.

- Requires preheating and slow cooling – Without proper preparation, welding can cause the metal to break instead of fixing it.

- Welding can change the metal structure – The high heat alters cast iron’s properties, sometimes making it weaker.

- Not always practical – If the part is large, expensive, or hard to move, welding may not be an option.

Best Methods to Repair Cast Iron Cracks Without Welding

There are several ways to repair cracked cast iron without welding. Each method has its own advantages depending on the type of crack and the purpose of the repair.

Using Epoxy or Metal-filled Epoxy Compounds

One of the easiest and most effective ways to fix cast iron cracks without welding is by using epoxy. Metal-filled epoxy, such as JB Weld, is designed to bond with metal and restore strength.

Steps to Repair with Epoxy:

- Clean the cracked area – Use a wire brush or sandpaper to remove rust, grease, and dirt.

- Degrease the surface – Wipe the area with acetone or rubbing alcohol for better adhesion.

- Mix the epoxy – Follow the instructions on the package to combine the resin and hardener.

- Apply the epoxy – Use a putty knife to push the epoxy into the crack and spread it evenly.

- Let it cure – Give it at least 24 hours to fully harden before using the part.

This method works well for small cracks, non-load-bearing parts, and areas that don’t experience high heat.

Cold Stitching (Metal Locking)

Cold stitching is one of the most reliable ways to fix cast iron cracks permanently. It involves drilling and inserting metal pins to hold the cracked sections together. This method doesn’t require heat, so it won’t introduce new cracks.

Steps to Repair with Cold Stitching:

- Drill small holes along the crack – Start at one end and drill along the length of the crack.

- Insert metal stitching pins – Special metal pins (cast iron locks) are tapped into the holes.

- Overlap the pins – Continue inserting pins so they overlap slightly, locking the crack together.

- Seal with metal sealant – This helps prevent future cracking and adds extra strength.

- Grind or smooth the surface – Once the repair is complete, you can sand it down for a smooth finish.

This method is ideal for large cracks or structural cast iron repairs, like engine blocks and heavy machinery.

Brazing with a Torch and Brazing Rod

If you need a stronger repair than epoxy but don’t want to weld, brazing is a great option. Brazing uses a filler rod that melts at a lower temperature than welding, so it won’t damage the cast iron.

Steps to Repair with Brazing:

- Clean the crack – Use a grinder or wire brush to remove debris and oxidation.

- Preheat the metal – Slowly heat the cast iron to about 500°F to reduce stress.

- Apply flux – A brazing flux will help the filler metal bond properly.

- Melt the brazing rod – Use a torch to heat the filler metal and allow it to flow into the crack.

- Cool slowly – Let the part cool down at room temperature to prevent new cracks.

Brazing is stronger than epoxy and is good for parts exposed to heat, but it does require some heating.

Threaded Inserts (Drilling and Tapping a Patch)

For larger cracks or broken sections, drilling and tapping a metal patch can be a strong, long-lasting fix.

Steps to Repair with Threaded Inserts:

- Drill along the crack – Create threaded holes for inserting screws or bolts.

- Tap the holes – Use a threading tool to create threads for the bolts.

- Insert screws or bolts – Tighten them to pull the crack together.

- Seal with high-strength adhesive – This prevents leaks and strengthens the repair.

- Grind smooth – If necessary, sand down the surface for a finished look.

This method is best for structural cast iron repairs that need extra strength.

Using Cast Iron Repair Putty

Some high-temperature metal putties are designed specifically for cast iron repairs. These are great for sealing leaks in cast iron pipes, radiators, and engine blocks.

Steps to Repair with Metal Putty:

- Clean the area – Remove rust, dirt, and oil.

- Mix and apply the putty – Knead it and press it into the crack.

- Let it harden – Allow 24 hours for a full cure.

- Smooth and paint if needed – Once dry, it can be sanded or painted.

Metal putty works well for sealing leaks and minor cracks but isn’t as strong as stitching or brazing.

Choosing the Right Repair Method

Here’s a comparison table to help you choose the best repair method:

| Repair Method | Strength | Best For | Heat Required | Difficulty |

|---|---|---|---|---|

| Epoxy | Low to Medium | Small cracks, non-structural parts | No | Easy |

| Cold Stitching | High | Structural repairs, large cracks | No | Moderate |

| Brazing | High | Parts exposed to heat and stress | Yes | Moderate |

| Threaded Inserts | Very High | Heavy-duty repairs, large breaks | No | Difficult |

| Metal Putty | Medium | Leaks, minor cracks | No | Easy |

Preventing Future Cracks in Cast Iron

Once you’ve repaired the crack, it’s important to take steps to prevent future damage. Here are some tips:

- Avoid sudden temperature changes – Cast iron is sensitive to rapid heating and cooling.

- Support heavy cast iron parts properly – Reduce stress points that can lead to cracks.

- Use anti-rust coatings – Prevent corrosion that weakens cast iron over time.

- Inspect for hairline cracks – Small cracks can spread if left untreated.

Conclusion

Fixing a cracked cast iron piece without welding is absolutely possible if you use the right technique. Whether you choose epoxy, cold stitching, brazing, threaded inserts, or repair putty, the key is choosing the method that best suits the crack size, location, and strength requirements.

If you’re working on a small household item, epoxy or metal putty might be enough. For engine blocks or machine parts, cold stitching or brazing will give the best results. Taking your time with the repair and following the right steps will help ensure a long-lasting fix.

FAQs

Can I fix a cracked cast iron engine block without welding?

Yes, cold stitching or brazing are the best methods for engine blocks.

Is JB Weld strong enough for cast iron repairs?

It works well for small cracks and non-structural repairs, but not for load-bearing parts.

How do I stop a crack in cast iron from spreading?

Drill small holes at both ends of the crack to prevent it from growing.

Does heat weaken cast iron?

Yes, excessive heat can make cast iron more brittle and prone to cracking.

By using the right repair method, you can restore the strength and function of cast iron without needing a welder!