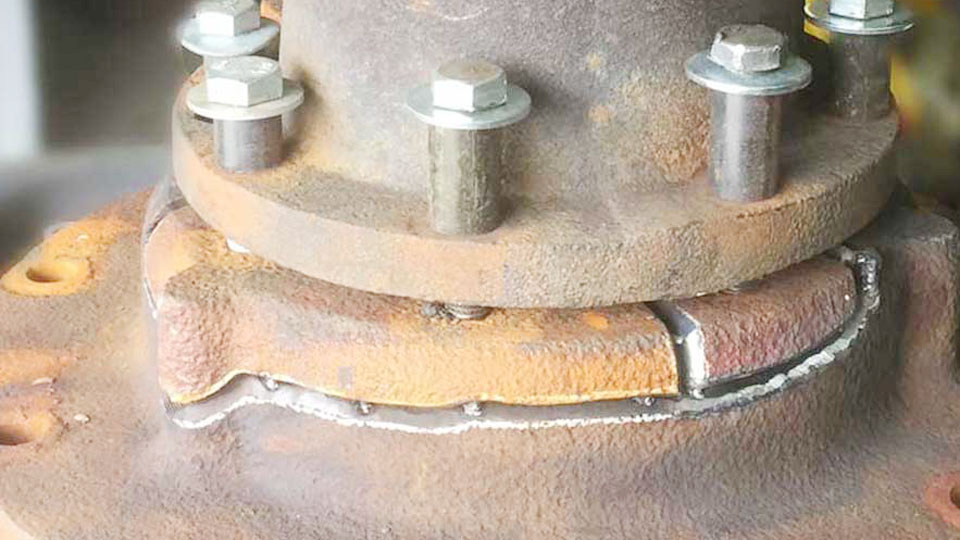

JB Weld is one of the best solutions for repairing broken or cracked cast iron. Whether it’s a cracked engine block, a damaged exhaust manifold, or a broken cast iron pipe, JB Weld can be a lifesaver when welding isn’t an option. I’ve had my fair share of cast iron repairs, and JB Weld has never failed to impress me when used correctly.

Image by fmwsolutions

If you’re dealing with a cast iron repair and wondering if JB Weld will do the job, the good news is—it absolutely can.

Success depends on how well you prepare the surface and apply the epoxy. Let me walk you through the entire process, step by step, so you can get a strong, long-lasting bond on your cast iron repair.

What is JB Weld?

JB Weld is a two-part epoxy adhesive that works as a cold weld. It creates an incredibly strong bond when applied correctly, making it an excellent alternative to traditional welding, especially on materials like cast iron. Once cured, JB Weld is heat-resistant, waterproof, and can even be drilled, sanded, and painted.

The standard JB Weld formula has a tensile strength of 3960 PSI, which means it’s strong enough for most cast iron repairs. There are also high-heat versions available if you’re working on something like an exhaust manifold.

When to Use JB Weld on Cast Iron

JB Weld is best for small to medium cracks or breaks in cast iron where traditional welding isn’t an option. It works great in situations like:

- Cracked engine blocks

- Broken exhaust manifolds

- Damaged cast iron stoves

- Plumbing and pipe repairs

- Industrial machinery and tools

If the crack or break is too large, welding or replacing the part might be a better solution. But for most DIY repairs, JB Weld is more than enough.

How to Use JB Weld on Cast Iron

Using JB Weld on cast iron isn’t just about applying the epoxy and hoping for the best. The key to success is in the preparation. Here’s the process I follow for the best results.

Step 1: Gather Your Materials

Before you begin, make sure you have everything you need:

- JB Weld (Original or high-heat version, depending on the repair)

- Sandpaper or a wire brush

- Acetone or rubbing alcohol

- Clean cloth or paper towels

- Clamps (if needed)

- Putty knife or applicator

- Gloves

Step 2: Clean the Surface Thoroughly

Cast iron often has dirt, rust, grease, or oil on its surface. These contaminants can prevent JB Weld from bonding properly.

- Start by removing grease and oil using acetone or rubbing alcohol. Wipe the area thoroughly with a clean cloth.

- Use sandpaper or a wire brush to roughen the surface. This helps JB Weld grip the metal better.

- Wipe down the area one more time to remove any dust or debris.

A clean, rough surface is essential for a strong bond. If there’s any oil or rust left, JB Weld won’t stick properly.

Step 3: Mix the JB Weld Epoxy

JB Weld comes in two separate tubes—resin and hardener. You’ll need to mix them in equal parts.

- Squeeze out equal amounts of both components onto a disposable surface.

- Mix them together using a putty knife or a small stick. Keep mixing until the color is uniform (usually a dark gray).

You’ll have about 15-25 minutes of working time before the epoxy starts to set, so don’t waste any time.

Step 4: Apply the JB Weld to the Cast Iron

Now it’s time to apply the mixed epoxy to the damaged area.

- Use a putty knife or applicator to spread the JB Weld evenly over the crack or break.

- Make sure to press it into the crack to ensure full coverage.

- If the crack is deep, apply multiple thin layers instead of one thick layer for better strength.

For broken pieces, press them together firmly and use clamps to hold them in place while the JB Weld cures.

Step 5: Let It Cure Properly

JB Weld doesn’t harden instantly. It needs time to cure.

- It will set in about 4-6 hours but won’t fully cure for 24 hours.

- Keep the part undisturbed and at room temperature while it cures.

If you’re working on a high-heat application, like an exhaust manifold, make sure you’re using a high-temperature JB Weld variant.

Step 6: Sand and Paint (Optional)

Once the JB Weld has fully cured, you can sand it down to smooth out the surface.

- Use fine-grit sandpaper to shape the repair area.

- If needed, you can paint over JB Weld to match the rest of the cast iron.

At this point, your repair is complete, and the cast iron should be as strong as ever.

Strength and Durability of JB Weld on Cast Iron

JB Weld forms a very strong bond with cast iron, but it’s important to understand its limitations.

| Property | JB Weld (Original) | High-Heat JB Weld |

|---|---|---|

| Tensile Strength | 3960 PSI | 5020 PSI |

| Heat Resistance | 550°F | 1000°F |

| Set Time | 4-6 hours | 6-8 hours |

| Full Cure Time | 24 hours | 24 hours |

| Sandable & Paintable | Yes | Yes |

For applications that involve extreme heat, like an engine block or exhaust system, using the high-heat version is essential.

Mistakes to Avoid When Using JB Weld on Cast Iron

I’ve seen a lot of people make simple mistakes when using JB Weld, which leads to weak repairs. Here’s what to watch out for:

- Not cleaning the surface properly – Any grease, oil, or rust will prevent JB Weld from bonding.

- Applying too much at once – Thin layers work better than one thick glob of epoxy.

- Not letting it cure fully – If you try to use the part before 24 hours, the bond won’t be as strong.

- Using the wrong type – Always use high-heat JB Weld for hot applications.

Avoiding these mistakes will ensure your repair holds up for the long run.

When JB Weld Might Not Be the Best Option

While JB Weld works wonders on cast iron, there are situations where it might not be the best choice.

- For load-bearing parts – If the cast iron part supports heavy weight, a welded repair is usually stronger.

- For structural components – In critical structural applications, welding is more reliable.

- For extreme vibrations – If the part experiences constant vibrations, welding or bolting may be better.

If your repair falls into these categories, consider professional welding instead.

Conclusion

JB Weld is an excellent solution for repairing cracked or broken cast iron when welding isn’t an option. With the right preparation and application, it forms a strong, durable bond that can last for years.

The key to success is cleaning the surface thoroughly, mixing the epoxy correctly, and giving it enough time to cure. Whether you’re fixing an engine block, a cast iron stove, or a pipe, following these steps will ensure a reliable repair.

If you need a quick and effective cast iron fix, JB Weld is one of the best choices out there.

Frequently Asked Questions

Can JB Weld withstand high temperatures?

Yes, but for extreme heat applications, use the high-temperature JB Weld formula.

How long does JB Weld last on cast iron?

When applied correctly, JB Weld can last for years, even in demanding conditions.

Can JB Weld be drilled and sanded?

Yes, once it’s fully cured, you can drill, sand, and even paint over it.

Is JB Weld stronger than welding?

No, traditional welding is still stronger, but JB Weld is a great alternative for non-structural repairs.

If you’ve got a cast iron repair to tackle, JB Weld can save the day. Just take your time, follow these steps, and you’ll have a solid fix in no time.