If you’ve ever worked with cast iron, you know how tough and durable it is. But despite its strength, it can still crack or break under stress. Whether it’s an old cast iron skillet, a broken machine part, or a cracked engine block, fixing cast iron without welding is possible.

Image by reddit

I’ve had my fair share of dealing with broken cast iron pieces, and I know how frustrating it can be. You might think welding is the only solution, but not everyone has access to a welder or the skills to use one. Fortunately, there are several reliable methods to repair cast iron without welding.

If you’re looking for ways to fix cast iron without welding, I’ll walk you through the best techniques. These methods work well for both structural and cosmetic repairs, helping you restore your cast iron without the complexity of welding.

Cast Iron and Why It’s Hard to Repair

Cast iron is a brittle metal that doesn’t bend like steel. It contains a high percentage of carbon, which makes it strong but prone to cracking. When cast iron breaks, it doesn’t stretch—it fractures. That’s why welding cast iron is tricky, as it can crack even more if not done correctly.

The good news is that you can fix cast iron without welding by using strong adhesives, brazing, cold metal stitching, and other methods. The key is choosing the right technique based on the size, location, and type of damage.

Best Methods to Fix Cast Iron Without Welding

There are several ways to repair cast iron without welding. Each method has its own advantages, and I’ll explain how they work so you can choose the best one for your situation.

Using Epoxy Adhesive for Small Repairs

Epoxy is one of the easiest and most effective ways to fix cast iron. It works best for small cracks, holes, or broken pieces that don’t bear too much weight.

How to Use Epoxy on Cast Iron:

- Clean the broken area with a wire brush and degreaser to remove dirt and oil.

- Roughen the surface with sandpaper to help the epoxy stick better.

- Mix the epoxy according to the instructions. Some epoxy adhesives come in two parts that need to be combined before use.

- Apply the epoxy generously to the broken area.

- Hold the pieces together firmly for the recommended curing time.

- Let the epoxy cure completely before using the repaired cast iron.

Epoxy works well for household items like cast iron pans, decorative pieces, and machinery parts that don’t undergo heavy stress.

Brazing – A Strong Alternative to Welding

Brazing is another effective way to repair cast iron without welding. It involves using a filler metal, such as bronze or brass, to bond the broken pieces together. The process requires a torch to heat the metal but doesn’t reach the high temperatures of welding, reducing the risk of further cracking.

How to Braze Cast Iron:

- Clean the damaged area thoroughly with a wire brush and degreaser.

- Preheat the cast iron slowly with a propane or oxy-acetylene torch to prevent thermal shock.

- Apply a brazing rod to the crack while heating the area. The filler metal will melt and flow into the crack, creating a strong bond.

- Allow the cast iron to cool down gradually to prevent new cracks.

Brazing is ideal for repairing engine blocks, exhaust manifolds, and other high-stress cast iron parts.

Cold Metal Stitching for Large Cracks

Cold metal stitching is one of the best methods for fixing large cracks in cast iron without welding. This method has been used for decades in industrial repairs, and it works exceptionally well for structural components.

How Cold Metal Stitching Works:

- Drill small holes along both sides of the crack.

- Insert metal pins or stitching fasteners into the holes to hold the crack together.

- Use a special tool to tighten the fasteners, creating a strong mechanical bond.

- Seal the repair with epoxy or another bonding agent for added strength.

Cold stitching is commonly used for industrial cast iron repairs, including engine blocks and heavy machinery. It’s a permanent fix that restores the structural integrity of the metal.

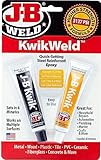

Using JB Weld for Quick and Easy Repairs

JB Weld is a popular epoxy-based adhesive specifically designed for metal repairs. It creates a strong bond and can withstand high temperatures, making it a great option for fixing cast iron.

Steps to Fix Cast Iron with JB Weld:

- Clean and sand the surface to remove rust, grease, and paint.

- Mix the JB Weld components together until you get a uniform color.

- Apply the mixture to the damaged area and press the parts together.

- Allow it to cure for at least 24 hours for maximum strength.

JB Weld is excellent for repairing small cracks, holes, and broken parts. It’s a cost-effective and easy solution for minor cast iron damage.

Threaded Inserts for Reinforcing Weak Areas

For parts that have broken bolt holes or damaged threads, using threaded inserts can restore the strength of the cast iron.

How to Install a Threaded Insert:

- Drill out the damaged hole to fit the insert.

- Tap new threads into the hole using a threading tool.

- Screw the threaded insert into place.

- Secure it with a bonding agent if necessary.

This method is useful for repairing engine blocks, machinery parts, and any cast iron components that require secure bolt connections.

Comparing Cast Iron Repair Methods

Each method has its strengths, so choosing the right one depends on the type of damage.

| Repair Method | Best For | Strength | Ease of Use |

|---|---|---|---|

| Epoxy Adhesive | Small cracks and non-structural parts | Moderate | Easy |

| Brazing | High-stress components | Strong | Moderate |

| Cold Metal Stitching | Large structural cracks | Very strong | Difficult |

| JB Weld | Quick and small repairs | Strong | Easy |

| Threaded Inserts | Fixing broken bolt holes | Strong | Moderate |

Preventing Future Cast Iron Damage

Once you’ve repaired your cast iron, it’s important to take steps to prevent future damage. Here are some tips:

- Avoid sudden temperature changes – Cast iron can crack if heated or cooled too quickly.

- Use proper support – Don’t put too much pressure on weak areas.

- Keep it clean and dry – Rust can weaken cast iron over time.

- Check for signs of stress – Regular inspections can help catch small cracks before they become bigger problems.

Conclusion

Fixing cast iron without welding is not only possible but also highly effective when done correctly. Whether you choose epoxy, brazing, cold metal stitching, JB Weld, or threaded inserts, the right method depends on the size and type of damage.

I’ve used many of these methods myself, and I can tell you they work if you follow the right steps. If you have a broken cast iron piece, don’t throw it away just yet. With a little effort, you can bring it back to life and save yourself a lot of money.

So, go ahead and try one of these repair techniques—I promise you’ll be surprised at how well they work!

FAQs

Can you fix a cracked cast iron without welding?

Yes, you can repair cracked cast iron using epoxy, brazing, cold metal stitching, or JB Weld.

Is JB Weld strong enough for cast iron?

Yes, JB Weld creates a strong bond and can handle high temperatures, making it a good option for minor cast iron repairs.

What is the strongest method to repair cast iron?

Cold metal stitching is the strongest non-welding method for repairing large cracks in cast iron.

Can I use super glue to fix cast iron?

No, super glue is not strong enough for cast iron repairs. Epoxy or JB Weld is a much better option.

How do I prevent cast iron from cracking again?

Avoid rapid temperature changes, handle it with care, and keep it rust-free to prevent future damage.