When it comes to welding, heat input is one of the most important factors that can affect the strength, quality, and performance of a weld.

If you apply too much heat, you risk weakening the metal or causing warping. If you don’t use enough heat, the weld might not fully penetrate, leading to weak joints.

Photos by kobelco-welding

I’ve worked with different welding processes, and I can tell you that understanding how to calculate heat input is essential if you want strong, reliable welds.

If you’re a beginner or an experienced welder, learning how to measure and control heat input can help you improve your welding technique and ensure the best results.

Let’s break it down step by step, in a way that’s easy to understand and apply in real welding jobs.

What is Heat Input in Welding?

Heat input refers to the amount of heat energy transferred to the metal during welding. It’s measured in Joules per millimeter (J/mm) or Joules per inch (J/in) and plays a crucial role in determining weld penetration, microstructure, and overall weld quality.

Different welding processes, such as MIG, TIG, and stick welding, require different levels of heat input. If the heat input is too high, it can cause excessive distortion, cracking, or burn-through. On the other hand, low heat input might lead to lack of fusion or weak welds.

Why is Heat Input Important?

- Controls weld penetration – Ensures proper fusion between base metals.

- Prevents overheating – Avoids burn-through and excessive warping.

- Maintains mechanical properties – Affects the hardness and strength of the welded joint.

- Reduces defects – Helps prevent cracks, porosity, and undercutting.

- Ensures code compliance – Many welding standards (such as AWS and ASME) have heat input limits.

Formula for Calculating Heat Input

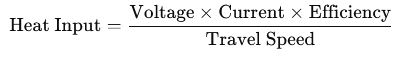

The most common formula for calculating heat input in welding is:

Where:

- Voltage (V) – The voltage used during welding (Volts).

- Current (I) – The welding current (Amps).

- Efficiency (η\etaη) – The thermal efficiency factor of the welding process.

- Travel Speed (S) – The speed at which the weld is made (mm/min or in/min).

Let’s go through each component in detail.

Components of Heat Input

Voltage (V)

Voltage controls arc length and influences the amount of heat transferred to the workpiece. Higher voltage increases heat input, while lower voltage reduces it.

Current (I)

Current determines the arc intensity and directly affects penetration. Higher current means more heat, leading to deeper weld penetration.

Welding Process Efficiency (η\etaη)

Each welding process has a different efficiency because some energy is lost as radiation, spatter, or heat dissipation. Here are the typical efficiency values:

| Welding Process | Efficiency Factor (η\etaη) |

|---|---|

| SMAW (Stick) | 0.8 |

| GMAW (MIG) | 0.9 |

| GTAW (TIG) | 0.6 |

| FCAW (Flux-Cored) | 0.85 |

| SAW (Submerged Arc) | 1.0 |

Travel Speed (S)

Travel speed refers to how fast the welding torch or electrode moves. It’s measured in millimeters per minute (mm/min) or inches per minute (in/min). Faster travel speeds result in lower heat input, while slower speeds increase heat input.

Step-by-Step Example of Heat Input Calculation

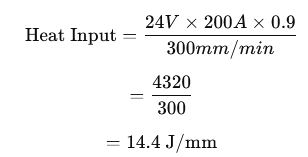

Let’s say we are doing a MIG weld with the following parameters:

- Voltage = 24V

- Current = 200A

- Efficiency = 0.9 (for MIG)

- Travel Speed = 300 mm/min

Now, using the formula:

This means the heat input for this weld is 14.4 Joules per millimeter.

How to Control Heat Input

Once you know how to calculate heat input, the next step is controlling it to ensure high-quality welds. Here are some effective ways to manage heat input:

Adjust Voltage and Current

- Lowering the voltage and current reduces heat input, preventing overheating.

- Increasing voltage and current increases heat input, improving fusion and penetration.

Modify Travel Speed

- Faster travel speed reduces heat input, helping prevent burn-through.

- Slower travel speed increases heat input, ensuring proper fusion.

Choose the Right Welding Process

- MIG and TIG welding require different heat inputs.

- Stick welding (SMAW) has a medium heat input, while Submerged Arc Welding (SAW) has high heat input due to its efficiency.

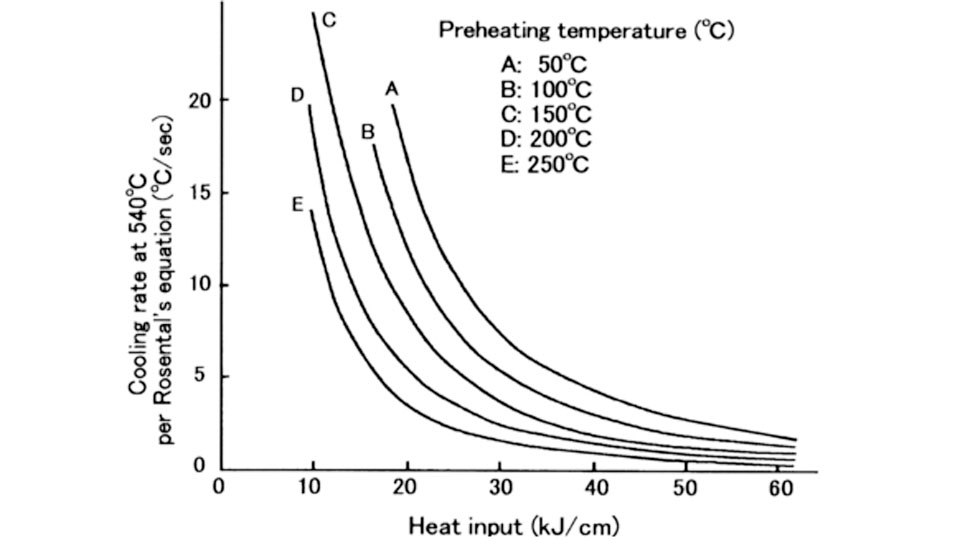

Use Interpass Temperature Control

For multi-pass welds, monitoring interpass temperature is important. Excessive heat buildup can lead to poor mechanical properties, so allow the metal to cool between passes.

Effects of Too Much or Too Little Heat Input

| Heat Input | Effects on Weld |

|---|---|

| Too High | Excessive distortion, burn-through, cracks, large heat-affected zone (HAZ) |

| Too Low | Poor penetration, lack of fusion, weak weld strength, porosity |

Real-World Applications of Heat Input Control

In industries like construction, shipbuilding, and pipeline welding, heat input calculations help meet strict standards. For example:

- Structural welding – Ensuring beams and joints hold up under stress.

- Automotive welding – Preventing warping in thin sheet metal.

- Pipeline welding – Controlling heat input to avoid cracking in thick materials.

Conclusion

Understanding how to calculate heat input in welding helps you improve weld quality, prevent defects, and meet industry standards.

If you’re working on a small fabrication project or heavy-duty structural welding, controlling heat input is key to getting strong, reliable welds.

By using the simple formula and adjusting your voltage, current, and travel speed, you can optimize your welding process and achieve the best results.

FAQs

What is the formula for heat input in welding?

The formula is (Voltage × Current × Efficiency) ÷ Travel Speed.

How do I reduce heat input in welding?

You can increase travel speed, lower voltage, or reduce current.

Why is heat input important in welding?

It affects weld strength, penetration, distortion, and mechanical properties.

What happens if heat input is too high?

Excessive heat can cause warping, cracking, and a weakened weld zone.

What welding process has the highest heat input?

Submerged Arc Welding (SAW) has the highest heat input due to its 100% efficiency.