Welding cast iron with an arc welder can feel intimidating, especially if you’ve heard about how brittle and tricky cast iron can be. I remember my first time attempting it—I was nervous, worried about cracks, and unsure about the right approach. With the right techniques, patience, and a few tried-and-true tricks, arc welding cast iron can be done successfully.

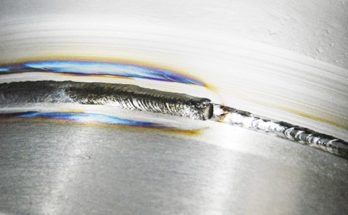

Image by roadkillcustoms

Cast iron is widely used in engine blocks, machinery, pipes, and even cookware, and when it breaks, replacing it isn’t always an option.

That’s where welding comes in. But cast iron doesn’t behave like mild steel—it’s more brittle and heat-sensitive, so controlling heat and using the right electrodes are key to getting a solid weld. Let’s go through everything you need to know about arc welding cast iron, step by step.

Cast Iron and Its Welding Challenges

| # | Preview | Product | |

|---|---|---|---|

| 1 |

|

5PCS Replacement Hardware Tips for ARC Welding Device Tips Accessories Parts Pro Plus Tip | Check Price on Amazon |

Before striking an arc, it’s important to understand what makes cast iron different from steel. The main issue with welding cast iron is its high carbon content (2-4%), which makes it hard, brittle, and prone to cracking.

Some of the biggest challenges with welding cast iron include:

- Heat Sensitivity – Cast iron doesn’t expand and contract like steel. Too much heat can cause cracks.

- High Carbon Content – The carbon in cast iron can cause a hard, brittle area near the weld (a heat-affected zone).

- Porosity – Contaminants in cast iron (oil, grease, and dirt) can cause bubbles or weak welds.

- Post-Weld Cracking – If the cooling rate isn’t controlled, cracks will form around the weld.

Knowing these challenges helps you prepare for a successful repair.

Choosing the Right Type of Cast Iron for Welding

Not all cast iron is the same. Some types weld better than others.

| Type of Cast Iron | Common Uses | Weldability |

|---|---|---|

| Gray Cast Iron | Engine blocks, pipes, machine parts | Difficult but possible |

| White Cast Iron | Hard surfaces, mining equipment | Nearly impossible to weld |

| Malleable Cast Iron | Pipe fittings, automotive parts | Can be welded with preheat |

| Ductile Cast Iron | Structural components, gears | Easier to weld than gray cast iron |

Gray cast iron is the most common type you’ll encounter. It can be welded, but requires careful heat control.

Selecting the Right Electrode for Arc Welding Cast Iron

Using the right electrode is one of the most important factors in getting a good weld.

| Electrode Type | Best For | Advantages | Disadvantages |

|---|---|---|---|

| Nickel (99% Ni) – ENi-CI | High-quality welds, machining | Strong, ductile welds | Expensive |

| Nickel-Iron (55% Ni) – ENiFe-CI | Strong welds, less cracking | Good fusion, machinable | Less ductile than pure nickel |

| Steel (ESt) Rods | Non-machinable repairs | Cheaper than nickel | Can be brittle |

| Cast Iron Rods | Similar metal welding | Good color match | More prone to cracking |

Nickel electrodes are the best choice if you want a strong, machinable weld. If you’re on a budget, steel electrodes can work, but they are harder to machine after welding.

Preparing Cast Iron for Welding

Good preparation makes or breaks a cast iron weld.

- Clean the Surface Thoroughly – Remove oil, grease, and paint using a wire brush, grinder, or acetone. Cast iron absorbs contaminants, which can lead to weld porosity.

- Preheat If Necessary – Some methods require preheating to 500-1200°F to reduce stress and prevent cracking.

- Bevel the Edges – If welding a crack or broken piece, grind a V-groove along the joint to improve penetration.

- Drill Stop Holes – If welding a crack, drill a small hole at each end to prevent it from spreading.

- Use Clamps to Hold the Workpiece – This prevents movement and minimizes warping.

Skipping preparation can lead to weak welds or cracks forming after cooling.

Setting Up Your Arc Welder for Cast Iron

To avoid heat-related problems, you’ll need the right settings and technique.

- Polarity: Use DC reverse polarity (DCEP) for nickel electrodes.

- Amperage: Use low amperage settings to control heat.

- Arc Length: Keep a short arc to focus the heat and avoid excessive penetration.

Here’s a general guide for amperage settings:

| Electrode Size | Amperage Range |

|---|---|

| 3/32″ (2.4mm) | 60-90A |

| 1/8″ (3.2mm) | 80-110A |

| 5/32″ (4.0mm) | 100-130A |

Start on the lower end of the range and increase only if needed. Too much heat will cause cracking.

Welding Techniques for Cast Iron

Since cast iron cracks easily, you need a slow, controlled approach when welding.

- Short Weld Beads – Use small, 1-inch welds instead of long continuous beads to control heat.

- Skip Welding – Weld in different spots instead of one continuous pass to spread out heat.

- Peening the Weld – Lightly tapping the weld with a hammer reduces stress and prevents cracks.

- Cooling Slowly – Never quench cast iron. Let it cool naturally in sand, an oven, or under an insulating blanket.

Rushing the process leads to cracks and failure. Take your time!

Avoiding Cracking and Warping

One of the biggest frustrations with welding cast iron is post-weld cracking. Here’s how to prevent it:

- Preheat before welding – Reduces stress buildup.

- Keep interpass temperature low – Let the workpiece cool slightly before the next pass.

- Use peening between welds – Helps reduce internal stress.

- Post-weld slow cooling – The slower it cools, the stronger the weld.

Finishing the Weld

Once the welding is done, you’re not finished yet.

- Grind the Weld Smooth – If needed for aesthetics or machining, smooth out the weld with a grinder.

- Check for Cracks – Look closely for signs of cracks forming after cooling.

- Apply Post-Weld Heat Treatment – Some welds may require additional stress-relieving heat treatment to prevent future cracks.

Proper finishing extends the life of the repair.

Common Mistakes to Avoid

Arc welding cast iron isn’t hard if you avoid these common mistakes:

- Skipping preheat – Causes immediate cracking.

- Using too much heat – Weakens the cast iron and makes it more brittle.

- Choosing the wrong electrode – Using mild steel rods leads to weak, brittle welds.

- Welding too fast – High heat input can cause internal stress and fractures.

- Rapid cooling – Never quench or force-cool a cast iron weld.

Conclusion

Arc welding cast iron takes patience and the right approach, but once you learn the techniques, it’s a valuable skill. Controlling heat, choosing the right electrode, and cooling slowly are the biggest factors in getting a successful weld.

If you’re welding cast iron for the first time, take it slow and focus on managing heat. With the right methods, you can repair cast iron without fear of cracks or weak joints. Keep practicing, and you’ll be welding cast iron like a pro in no time.

FAQs

Can I arc weld cast iron without preheating?

Yes, but only with nickel rods using a cold welding technique. Otherwise, preheating is recommended.

What is the best electrode for welding cast iron?

99% Nickel (ENi-CI) rods provide strong, machinable welds. 55% Nickel (ENiFe-CI) is a good alternative.

Why does cast iron crack after welding?

Rapid cooling or too much heat can cause stress cracks. Always cool it slowly.

Can you use mild steel rods to weld cast iron?

Yes, but the weld will be brittle and non-machinable. It’s not the best choice.

How do you prevent cast iron from cracking when welding?

Use low heat, short welds, peening, and slow cooling to reduce stress.