Welding is an art, a science, and a skill all wrapped into one. I’ve burned my fair share of rods, worked with many metals, and made a few mistakes that turned into great lessons.

One of the biggest challenges in welding—especially for beginners and even seasoned pros—is dealing with welding defects.

If you’re asking, “What are common welding defects and how do I avoid them?” — you’re already on the right track. Because knowing these issues is the first step to producing strong, clean, and reliable welds.

Let me walk you through everything I’ve learned about them, the types, causes, how to identify them, and most importantly, how to fix or prevent them.

What Are Welding Defects?

Welding defects are irregularities or flaws in a weld that can weaken the structure or cause it to fail under stress. Some defects are purely cosmetic, while others can pose a serious safety risk.

These flaws can be caused by a range of issues like improper technique, incorrect settings, contaminated materials, or even environmental conditions.

When you’re fabricating anything that needs to be strong—like a bridge joint, a pressure vessel, or even a car chassis—there’s no room for error. That’s why understanding welding defects is a must.

Why Welding Defects Matter

Weld defects don’t just make your work look bad—they can reduce structural integrity, cause leaks, cracks, or complete failures. In industries like construction, manufacturing, shipbuilding, and aerospace, even a small defect can lead to big disasters.

For example, a hairline crack might not be visible to the naked eye, but under pressure, it could grow and cause the weld to break. That’s why visual inspections, X-rays, ultrasonic testing, and dye penetrant tests are often used in quality assurance.

But you don’t need expensive tools to start spotting the basics. Let’s look at the most common welding defects I’ve come across and what you can do to prevent them.

Most Common Welding Defects and How to Avoid Them

Here’s a breakdown of the defects you’ll most likely see in welding work. I’ve also included what causes them and how you can avoid running into these problems.

| Welding Defect | Description | Common Causes | Prevention Tips |

|---|---|---|---|

| Porosity | Gas pockets or holes trapped inside the weld | Contaminated surface, moisture, wrong shielding gas | Clean materials, correct gas, proper technique |

| Cracks | Fractures in or near the weld | Rapid cooling, poor joint design, high stress | Preheat metal, slow cooling, good fit-up |

| Undercut | A groove melted into the base metal along the weld | High voltage, fast travel speed, poor angle | Lower voltage, steady speed, correct angle |

| Incomplete Fusion | Weld metal fails to fuse with base metal or prior bead | Low heat, dirty metal, poor technique | Clean base, adequate heat input |

| Incomplete Penetration | Weld doesn’t extend through the thickness of the joint | Poor joint access, low current | Proper joint design, higher amperage |

| Slag Inclusions | Slag trapped inside weld metal | Poor slag removal between passes | Clean between passes, maintain electrode angle |

| Spatter | Metal droplets around weld area | High amperage, incorrect polarity, dirty base metal | Adjust settings, clean surface |

| Overlap | Weld metal flows over base without bonding | Low travel speed, incorrect angle | Steady hand, right angle, control puddle |

| Burn-Through | Weld melts through thin base metal | High heat on thin material | Use backing bar, lower current |

| Distortion | Warping due to uneven heating and cooling | Excessive heat, poor clamping | Clamp properly, control heat input |

Let’s go into more detail for each of these, because understanding the “why” behind them really helps you fix them.

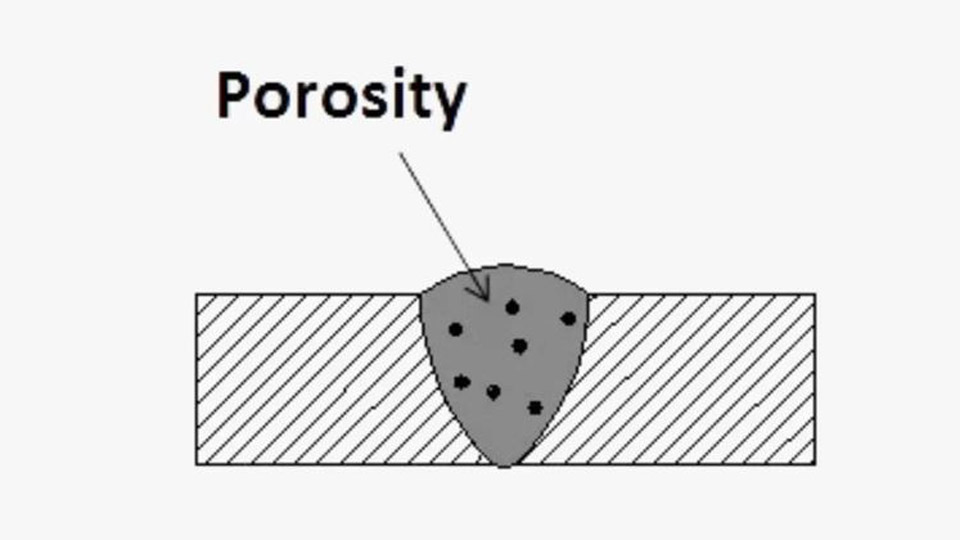

Porosity

Porosity happens when gas bubbles get trapped in the weld as it cools. The result looks like little pinholes or cavities, and it weakens the weld.

I once welded an exhaust pipe that had a bunch of porosity. It leaked gases right through the tiny holes. Turns out, the metal was oily and I didn’t clean it properly.

How to avoid it: Always clean your metal surfaces before welding—get rid of oil, paint, rust, and moisture. Make sure your shielding gas is flowing correctly and there’s no wind blowing it away. For TIG welding, especially, a draft can ruin your weld.

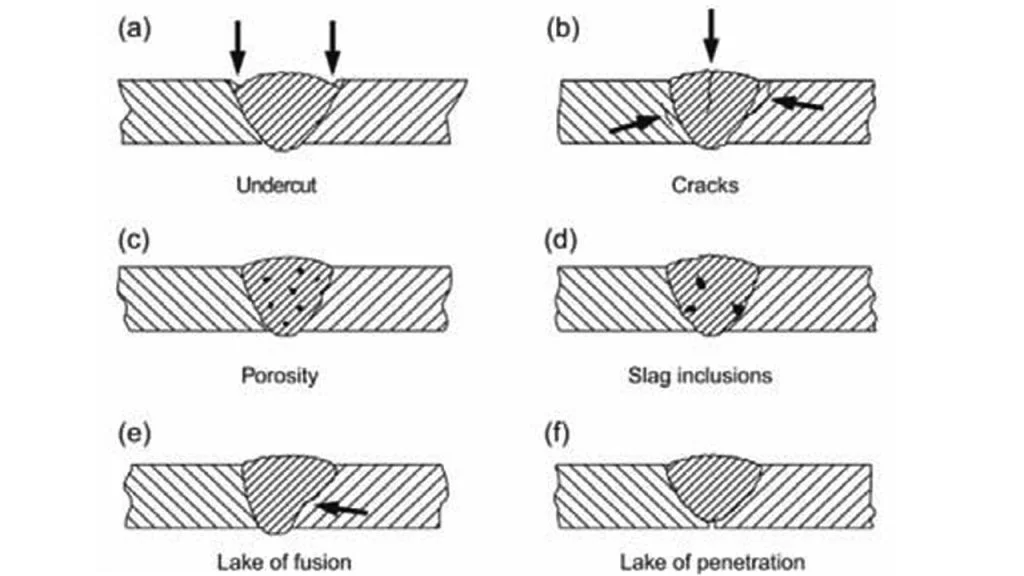

Cracks

Cracks are one of the most dangerous defects. These can form during or after welding. They’re usually caused by high residual stresses, improper cooling, or poor joint design.

I’ve seen cracks show up in thick stainless steel welds when they weren’t preheated properly.

How to avoid it: Use proper joint design, preheat thicker materials, and allow for slow and even cooling. Also, avoid excessive weld size, which can add unnecessary stress.

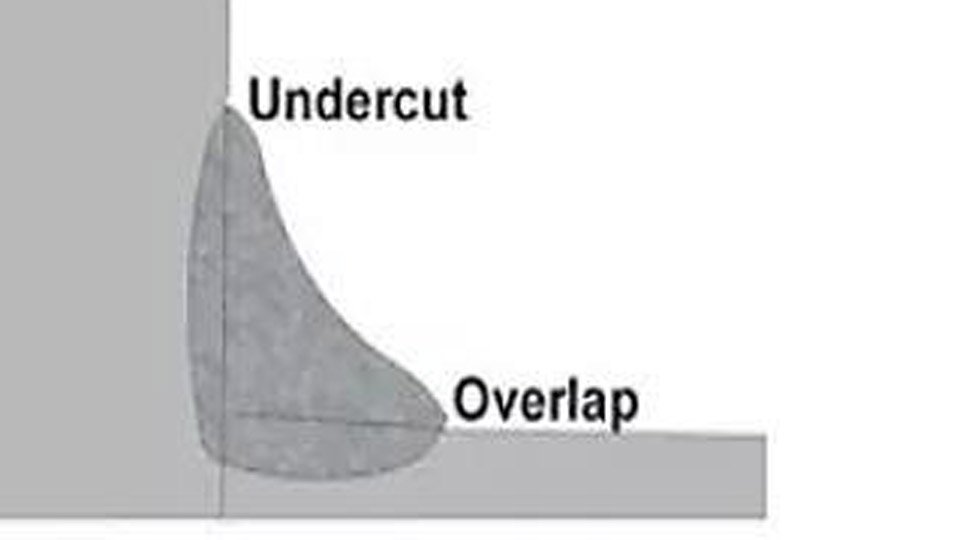

Undercut

Undercutting is when the base metal is melted away at the toe of the weld and not filled with weld metal. It creates a notch that’s a stress point.

This usually happens when you move too fast or crank up the voltage too high.

How to avoid it: Keep your travel speed steady, use the right voltage, and maintain a proper torch or electrode angle. A slight weave pattern can help fill the edges.

Incomplete Fusion

This one’s tricky. It looks like everything’s fine from the outside, but inside, the weld metal hasn’t fused properly with the base metal or previous welds.

It usually comes from using too low heat or not cleaning the surfaces well.

How to avoid it: Crank up your amperage if needed and clean the joint area thoroughly. Make sure your arc hits both the base and filler metal equally.

Incomplete Penetration

This is when the weld doesn’t go all the way through the joint. In critical applications like pipe welding, this could lead to leaks or joint failure.

I’ve had this happen when trying to weld thick plates without proper joint prep.

How to avoid it: Use a joint design that allows for full penetration and ensure enough heat input. Back gouging on the root side of a weld can help if you’re working from both sides.

Slag Inclusions

When slag gets trapped inside the weld metal, it forms an inclusion. This weakens the weld and can cause cracking under stress.

This often happens when you’re welding with stick or flux-core and don’t clean off the slag properly between passes.

How to avoid it: Always chip or grind away slag before laying down the next pass. Maintain a good arc length and electrode angle to prevent slag entrapment.

Spatter

Spatter is the annoying little droplets of molten metal that land around your weld. It’s more common in MIG and stick welding.

While not always structurally dangerous, it sure makes your work look messy.

How to avoid it:

Check your settings. Too much amperage or wrong polarity can increase spatter. Clean your base metal, and try using anti-spatter spray if you’re doing production work.

Overlap

Overlap happens when the weld metal spills over onto the base metal without fusing. It looks like a little overhanging lip.

It’s a sign you’re moving too slow or holding the torch at a bad angle.

How to avoid it: Speed up your travel just a little and focus on controlling the weld pool. Don’t let it roll out of control.

Burn-Through

Burn-through is when you melt right through the base metal, especially on thin material. It’s more common in MIG and TIG welding.

I once ruined a thin sheet metal panel because I didn’t turn down the heat.

How to avoid it: Lower your amperage and consider using pulse settings if you have that option. A copper backing bar can help draw away heat and prevent burn-through.

Distortion

Distortion happens when different parts of the metal expand and contract unevenly during welding. It leads to warped or twisted pieces.

This can ruin your entire project if you’re not careful.

How to avoid it: Use tack welds, clamp your pieces securely, and plan your welds to balance heat input. You can also use a sequence that spreads the heat evenly.

Final Thoughts on Identifying Welding Defects

If you ever wonder whether your weld is good or not—take a close look. Visual inspection is your first and most valuable tool. Look for smooth, even beads, and listen to the arc. A smooth arc sound usually means things are going well.

You don’t need X-ray equipment to catch most common problems. In many cases, your eyes, ears, and hands are enough to catch and correct issues early on.

How to Fix Welding Defects

Fixing weld defects depends on the type. Minor issues like spatter or undercut can be cleaned up or filled. But major ones, like cracks or incomplete fusion, often require grinding out the weld and redoing it properly.

General steps to fix defects:

- Identify the defect through visual inspection or NDT methods

- Remove the flawed section using a grinder or gouging tool

- Clean the area thoroughly

- Re-weld using the correct procedure

- Reinspect the repaired weld for new issues

How to Prevent Welding Defects Altogether

Here are my go-to habits that help keep weld defects to a minimum:

- Clean everything before welding

- Use the right filler metal and settings

- Maintain a steady hand and good travel speed

- Preheat thicker metals when needed

- Keep your electrode or torch angle consistent

- Don’t rush. Take your time to do it right the first time

It’s all about discipline and experience. The more you weld, the more you’ll recognize what works and what doesn’t.

Conclusion

Welding defects are part of the learning process. We’ve all been there. Whether you’re just starting or have been welding for years, paying attention to these common problems can save you a ton of frustration, rework, and even potential danger.

The good news is that most defects can be prevented by good preparation, proper technique, and understanding how your tools and materials behave.

Every weld you make is a chance to learn, and with each mistake, you get better. Stay patient, keep your eyes sharp, and take pride in doing it right.

Frequently Asked Questions

What causes porosity in welding?

Porosity is usually caused by contaminated metal surfaces, moisture, or issues with shielding gas. Always clean your base metal and ensure proper gas coverage.

How can I tell if my weld has a crack?

Cracks might be visible to the eye, especially under a bright light. For internal cracks, you may need dye penetrant testing or ultrasonic inspection.

What’s the difference between lack of fusion and lack of penetration?

Lack of fusion means the weld metal hasn’t bonded with the base or prior bead. Lack of penetration means the weld hasn’t gone deep enough through the joint thickness.

Is undercut a serious welding defect?

Yes, it can be. Undercut creates a weak point and can lead to cracking. It should be corrected or filled if found in a structural weld.

Can welding defects be repaired?

Absolutely. Many defects can be fixed by grinding out the problem area and re-welding it properly with the correct parameters.