When I first started TIG welding, I was always told that a foot pedal was an absolute necessity. It gave me control over the heat, helped me avoid overheating the metal, and allowed me to fine-tune the arc while I worked. But over time, I realized that TIG welding without a foot pedal is entirely possible—and in some cases, it’s even the preferred method.

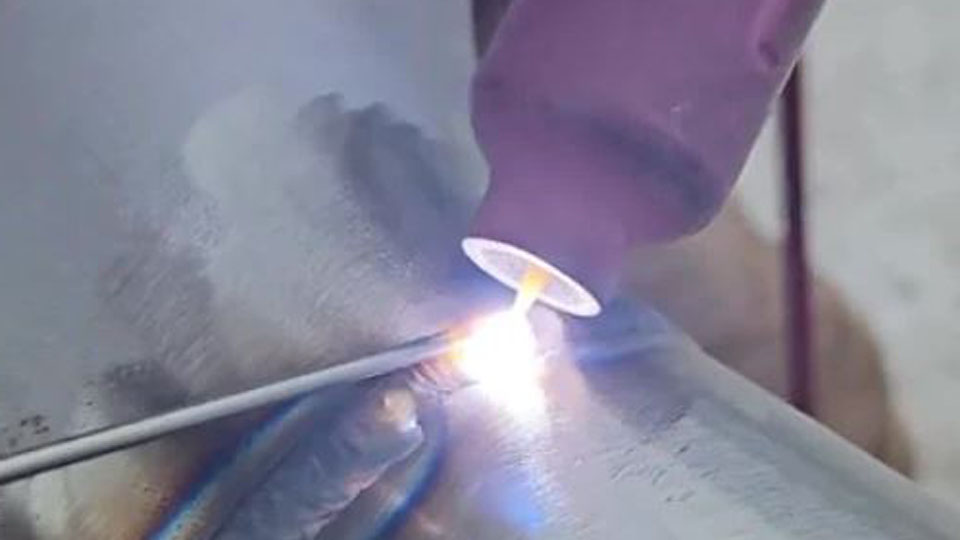

Image by yeswelder

If you’re wondering whether you can TIG weld without a foot pedal, the answer is yes. However, there are a few important factors to consider.

Some welders prefer a foot pedal for the fine control it provides, but others find that welding without one gives them more freedom, especially in certain situations. Let’s take a deep dive into the topic and break it all down.

How TIG Welding Works Without a Foot Pedal

In traditional TIG welding, a foot pedal acts like a throttle, letting you adjust the amperage as needed. This is particularly useful when welding thin materials or when you need to taper off the heat gradually.

But when you don’t have a foot pedal, you rely entirely on pre-set amperage or torch controls to regulate the heat. There are a few different ways to do this:

- Using a torch-mounted amperage control (slider or fingertip control)

- Setting a fixed amperage on the machine

- Using a machine with automatic or pulsed amperage control

Each method has its advantages and drawbacks, but they all allow you to weld effectively without using your foot.

Advantages of TIG Welding Without a Foot Pedal

There are actually some real benefits to welding without a foot pedal, especially depending on the situation.

More Freedom of Movement

When you’re welding in awkward positions—like overhead, inside a tight space, or on a large workpiece—a foot pedal can be inconvenient. It’s tough to press the pedal when you’re balancing on a ladder or crouching under a car.

Without a foot pedal, you have complete freedom to move, which can make the job a lot easier.

Ideal for Mobile Welding and Field Work

If you’re welding in a shop with a nice clean floor, using a foot pedal is easy. But if you’re working outside, in a field, or on a construction site, dragging around a foot pedal can be a hassle.

Many welders working in pipelines, automotive repair, and aerospace prefer not to use a foot pedal because it simplifies setup and makes the process more efficient.

Faster Setup and Less Clutter

A foot pedal means another cord to deal with, which can get tangled or take up space in your work area. Removing the pedal streamlines the setup, making it easier to start welding quickly.

Works Well for High Amperage Welding

For thicker metals, where you need consistent, high amperage, a foot pedal isn’t as necessary. In these cases, you don’t need to adjust the amperage as often, so setting it at a fixed level on the machine works just fine.

Disadvantages of TIG Welding Without a Foot Pedal

While there are benefits, welding without a foot pedal does come with a few challenges.

Less Precision and Heat Control

A foot pedal lets you fine-tune the heat as you weld, which is crucial for thin materials. Without it, you have to rely on pre-set amperage or torch controls, which may not give you the same level of precision.

Harder to Weld Thin Metals

When welding thin materials like stainless steel or aluminum, it’s easy to burn through if you can’t control the heat properly. A foot pedal allows you to back off the heat when necessary, which is much harder to do without one.

Learning Curve for Torch-Mounted Controls

Some welders use finger or thumb-controlled amperage adjustments on the torch, but this takes some getting used to. Unlike a foot pedal, which is gradual and intuitive, a slider or dial on the torch requires precise hand movements.

Not Ideal for Complex Welds

If you’re doing intricate welds that require frequent heat adjustments, a foot pedal is the best option. Welding without one can make things more difficult, especially for projects that need a lot of control.

Alternatives to a Foot Pedal in TIG Welding

If you don’t want to use a foot pedal, there are a few ways to still maintain some control over the amperage and get good results.

Fixed Amperage Settings on the Machine

One of the simplest ways to weld without a foot pedal is to set a fixed amperage on the TIG machine. This means you determine the best amperage for the material beforehand and weld at that power level the entire time.

While this works well for thicker metals, it can be tricky for thin materials where you’d typically need to adjust heat on the fly.

Torch-Mounted Amperage Controls

Some TIG torches come with finger or thumb-controlled amperage adjustments, allowing you to increase or decrease the heat as needed. These controls include:

- Rocker switch – Tap forward or backward to increase or decrease amperage.

- Slider control – Slide up or down to adjust amperage gradually.

- Dial control – Rotate a small knob on the torch for adjustments.

Using these takes some practice, but they allow for some heat control without a foot pedal.

Pulse TIG Welding

Many modern TIG welders have a pulse function, which automatically cycles the amperage up and down. This helps control heat input and can be useful when welding thin materials without a foot pedal.

Pulse welding is especially useful for stainless steel and aluminum, where overheating can cause warping or burn-through.

Comparison of TIG Welding With and Without a Foot Pedal

| Feature | With Foot Pedal | Without Foot Pedal |

|---|---|---|

| Heat Control | Excellent | Limited |

| Best for Thin Metals? | Yes | More difficult |

| Best for Thick Metals? | Works well | Works well |

| Ease of Movement | Limited (must use foot) | High (free movement) |

| Setup Time | Longer | Faster |

| Precision for Complex Welds | High | Medium |

| Best for Field Welding? | Not ideal | Yes |

When Should You TIG Weld Without a Foot Pedal?

There are certain times when welding without a foot pedal makes more sense than using one.

- Outdoor welding – Windy or rugged environments where setting up a foot pedal isn’t practical.

- Mobile welding jobs – Automotive, aerospace, or repair work where portability is needed.

- Tight spaces – Overhead welding or confined spaces where using a foot pedal is difficult.

- High-amperage welding – When working with thick metal that doesn’t require frequent heat adjustments.

Conclusion

TIG welding without a foot pedal is absolutely possible, and in many cases, it’s the better choice. If you’re working in the field, in tight spaces, or on thick metals, ditching the foot pedal can give you more flexibility and make the job easier.

That said, if you’re working with thin metals or need fine heat control, a foot pedal is still the best option. Alternatives like torch-mounted controls and pulse settings can help, but they take some practice.

Ultimately, whether or not you use a foot pedal comes down to what works best for you and the job at hand.

If you’re comfortable welding without one, it can make your setup simpler and give you more mobility. But if precision is your priority, keeping the foot pedal in your setup might be the smarter choice.

FAQs

Can I TIG weld aluminum without a foot pedal?

Yes, but it’s harder. Aluminum requires precise heat control, so a foot pedal or pulse setting is recommended.

What’s the best alternative to a foot pedal for TIG welding?

A torch-mounted amperage control (slider, rocker switch, or dial) is the next best option.

Is pulse welding useful for TIG welding without a foot pedal?

Yes, pulse settings can help regulate heat and prevent overheating, especially on thin materials.

Can I TIG weld stainless steel without a foot pedal?

Yes, but heat control is crucial. Using a fixed amperage setting or pulse welding can help manage heat input.

Should beginners learn TIG welding with or without a foot pedal?

Beginners should start with a foot pedal because it makes learning heat control much easier.