Welding aluminum can be tricky, and choosing the right welding wire size is a crucial part of getting it right. I’ve worked on various aluminum welding projects, and one thing I’ve learned is that the wrong wire size can lead to weak welds, excess spatter, or even burn-through.

If you’re working on thin aluminum sheets or heavy structural components, selecting the correct wire size will make all the difference in achieving strong, clean welds.

If you’re struggling to figure out which wire size to use for your aluminum welding project, don’t worry—I’ve got you covered.

Let’s go over everything you need to know about aluminum welding wire sizes, including a handy size chart to help you make the right choice.

Why Aluminum Welding Wire Size Matters

Aluminum is a soft and highly conductive metal, which makes it different from welding steel. It requires specific techniques, equipment settings, and most importantly, the correct welding wire size to ensure good penetration and a stable arc. Using the wrong wire size can cause a range of issues, such as:

- Burn-Through: A wire that’s too thick can cause excessive heat, leading to holes in thin aluminum.

- Lack of Fusion: A wire that’s too thin may not provide enough filler material, resulting in weak joints.

- Poor Feedability: Aluminum welding wires are softer than steel, making them more prone to feeding issues in the welding gun.

Common Aluminum Welding Wire Sizes

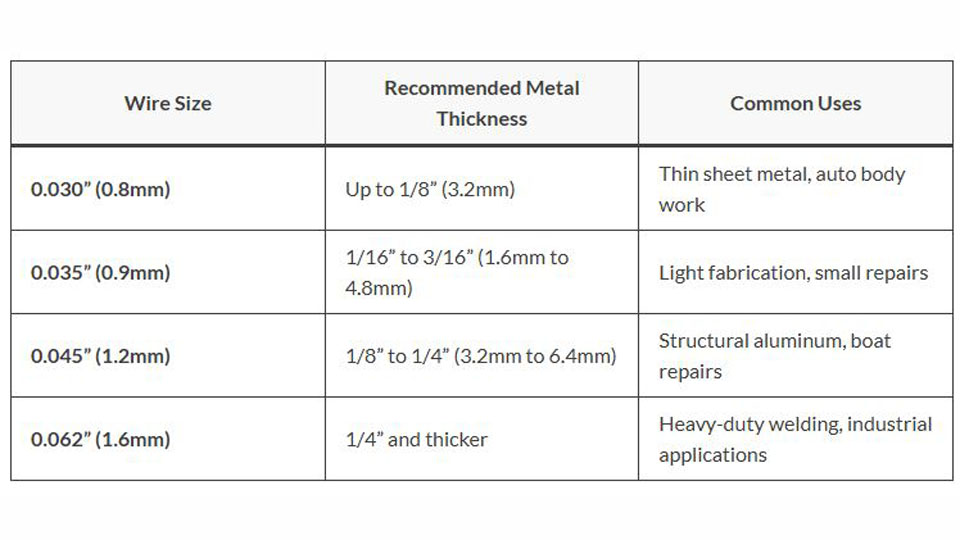

When selecting an aluminum welding wire size, you need to consider factors like the thickness of the base metal, the welding process, and the amperage setting. Here’s a general guideline:

| Wire Size | Recommended Metal Thickness | Common Uses |

|---|---|---|

| 0.030” (0.8mm) | Up to 1/8” (3.2mm) | Thin sheet metal, auto body work |

| 0.035” (0.9mm) | 1/16” to 3/16” (1.6mm to 4.8mm) | Light fabrication, small repairs |

| 0.045” (1.2mm) | 1/8” to 1/4” (3.2mm to 6.4mm) | Structural aluminum, boat repairs |

| 0.062” (1.6mm) | 1/4” and thicker | Heavy-duty welding, industrial applications |

How to Choose the Right Aluminum Welding Wire Size

If you’re not sure which wire size to use, here are a few key points to consider:

Consider the Thickness of the Base Metal

The thickness of the aluminum you’re welding is the most important factor in determining the right wire size. If you’re working with thin sheets, a smaller diameter wire like 0.030” is best because it melts faster and requires less heat. For thicker aluminum, you’ll need a larger wire like 0.045” or 0.062” to provide adequate filler material.

Match the Wire to Your Welding Process

The most common welding processes for aluminum are MIG (GMAW) and TIG (GTAW). The type of wire you use depends on which process you’re using:

- MIG Welding: Requires a spool of aluminum wire fed through a welding gun. Common sizes for MIG welding aluminum are 0.030”, 0.035”, and 0.045”.

- TIG Welding: Uses aluminum filler rods instead of a wire spool. These rods are typically 1/16” (0.062”) or thicker.

Amperage and Wire Size Compatibility

Your welding machine needs to be capable of handling the wire size you choose. If your amperage settings don’t match the wire diameter, you’ll either struggle to maintain a steady arc or risk excessive heat input. Here’s a rough guide for wire size and corresponding amperage:

| Wire Size | Recommended Amperage Range |

|---|---|

| 0.030” | 30-140A |

| 0.035” | 100-180A |

| 0.045” | 150-250A |

| 0.062” | 200-350A |

Using an appropriate amperage setting for your wire size will help ensure good penetration and minimal spatter.

Selecting the Right Aluminum Alloy Welding Wire

Not all aluminum welding wires are the same. The alloy composition of the wire should match or be compatible with the base material. Here are some common aluminum welding wires and their applications:

| Wire Type | Best for Welding | Key Features |

|---|---|---|

| ER4045 | 5000-series aluminum | High strength, good corrosion resistance |

| ER4043 | 6000-series aluminum | Good crack resistance, smooth finish |

| ER5356 | Marine and structural applications | Strong, high corrosion resistance |

If you’re unsure which wire alloy to choose, ER4043 is a good general-purpose wire, while ER5356 is better for structural and marine applications.

Troubleshooting Aluminum Welding Wire Issues

If you’re having trouble getting a good weld with aluminum, the problem might be related to your wire selection or feeding setup. Here are some common issues and how to fix them:

- Wire Feeding Issues: Aluminum wire is soft and can jam in the liner. Use a Teflon liner and a push-pull gun for smoother feeding.

- Excessive Burn-Through: Reduce the voltage and use a smaller wire size to avoid overheating thin metal.

- Lack of Fusion: Increase wire size or amperage to ensure better penetration.

Best Practices for Welding Aluminum with the Right Wire Size

To get the best results when welding aluminum, follow these tips:

- Use a Spool Gun for MIG Welding: This prevents wire feeding issues and improves weld quality.

- Set the Correct Shielding Gas: Pure argon is the best gas for aluminum welding.

- Keep the Wire Clean: Aluminum wire oxidizes quickly, so store it properly and clean it before use.

- Practice Proper Technique: Maintain a steady hand and use a push technique rather than a pull motion.

Conclusion

Choosing the right aluminum welding wire size is essential for achieving strong, clean welds. The thickness of your base metal, the welding process, and the amperage settings all play a role in determining the best wire size for your project.

Using the right combination of wire size, alloy type, and machine settings will ensure smooth feeding, good penetration, and minimal spatter.

I’ve made mistakes in the past by using the wrong wire size and learned the hard way how much of a difference it makes.

Once you get the hang of it, welding aluminum becomes a lot easier. This guide helps you make the right choice for your next aluminum welding project.

Frequently Asked Questions

What is the best aluminum welding wire size for thin metal?

For thin aluminum sheets, 0.030” or 0.035” wire works best because it melts quickly without excessive heat buildup.

Can I use 0.045” wire for thin aluminum?

It’s possible, but you’ll need to lower the amperage significantly to avoid burn-through. Smaller wire sizes are generally better for thin materials.

What is the difference between ER4043 and ER5356 aluminum welding wire?

ER4043 is softer and provides a smooth weld, making it good for general applications. ER5356 is stronger and more resistant to corrosion, making it ideal for structural and marine welding.

How do I prevent wire feeding issues when welding aluminum?

Use a spool gun or push-pull system, keep the wire clean, and use the correct drive rolls designed for soft aluminum wire.

Do I need to use a different shielding gas for aluminum welding?

Yes, aluminum welding requires 100% argon gas for the best results. Using the wrong gas can lead to poor arc stability and contamination.