One of the first things I learned when I started welding was that heat is everything. Too much, and you can burn through the metal or weaken the weld. Too little, and you won’t get proper fusion. That’s where heat input in welding comes into play.

Image by mdpi

Understanding heat input is crucial because it affects weld strength, penetration, distortion, and overall quality. If you’ve ever wondered why some welds turn out strong and smooth while others crack or warp, the answer often lies in how much heat was applied.

I’ll break down what heat input is, how it’s calculated, and why it matters. I’ll also share some real-world welding tips to help you control heat input for better welds.

What Is Heat Input in Welding?

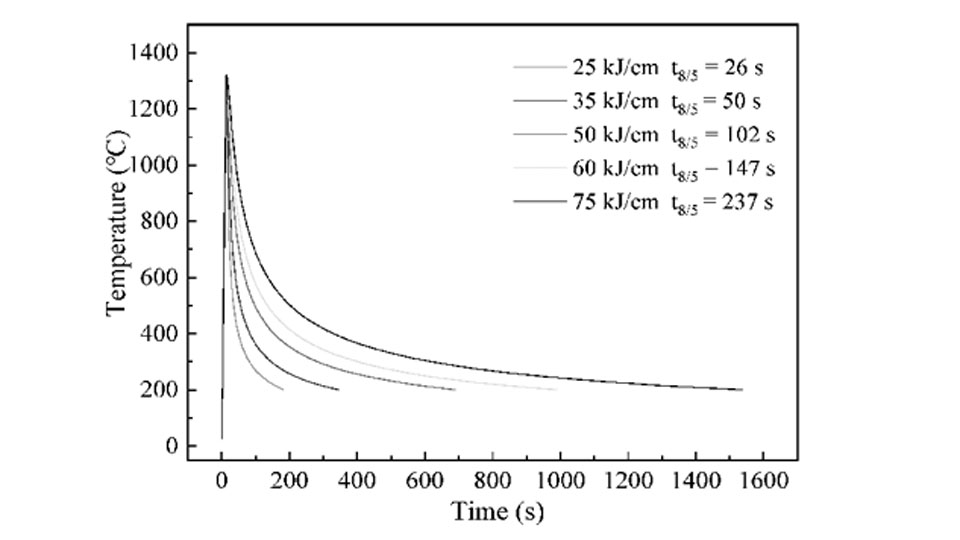

Heat input is the amount of energy transferred from the welding arc to the workpiece. It determines how much the base metal melts and how deep the weld penetrates.

Heat input affects everything in welding:

- Weld penetration – More heat gives deeper penetration.

- Distortion – Excessive heat can cause metal to warp.

- Microstructure – The heat affects the grain structure of the weld, impacting strength.

- Cooling rate – Higher heat input means slower cooling, which affects hardness.

When I first started welding, I didn’t pay much attention to heat input. I just set my machine, struck an arc, and hoped for the best. But over time, I realized that controlling heat input makes all the difference in getting consistent, high-quality welds.

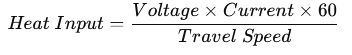

How Is Heat Input Calculated?

To measure heat input, welders use this formula:

Where:

- Voltage (V) is the welding arc voltage in volts.

- Current (I) is the welding amperage in amps.

- Travel speed (S) is the speed of welding in inches per minute.

The result is measured in Joules per inch (J/in).

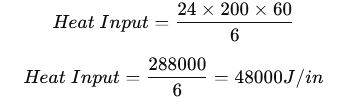

Here’s an example:

- Voltage: 24V

- Current: 200A

- Travel Speed: 6 inches per minute

This means 48,000 joules of energy are applied per inch of weld. The higher the number, the more heat is put into the weld.

Effects of High and Low Heat Input

Heat input isn’t just a number—it directly affects weld quality. Here’s what happens when you have too much or too little heat:

| Heat Input | Effect on Weld |

|---|---|

| High Heat Input | Deeper penetration, more distortion, slower cooling, softer weld metal. |

| Low Heat Input | Shallow penetration, faster cooling, risk of lack of fusion, harder weld metal. |

I’ve seen cases where welds failed simply because the heat input was too high, causing the metal to become brittle. On the other hand, low heat input can lead to weak fusion, which results in cracks or incomplete welds.

Factors That Influence Heat Input

Several welding variables affect how much heat gets into the weld:

Welding Process

Different welding methods apply heat differently.

- Stick welding (SMAW) tends to have higher heat input.

- MIG welding (GMAW) allows for more control over heat.

- TIG welding (GTAW) has low heat input but requires precision.

- Submerged arc welding (SAW) uses extremely high heat input for deep penetration.

Welding Parameters

- Higher voltage increases heat input.

- Higher amperage increases heat input.

- Faster travel speed reduces heat input.

Adjusting these settings can fine-tune your weld penetration and quality.

Material Thickness

Thicker metals require more heat to achieve full fusion, while thin materials overheat easily and need less heat input.

Type of Joint

- Butt joints need more heat for full penetration.

- Fillet welds often use lower heat input to avoid burn-through.

Electrode Type and Size

A larger electrode carries more current and delivers higher heat input, while a smaller electrode focuses heat in a smaller area.

How to Control Heat Input for Better Welds

If you want to produce strong and clean welds, controlling heat input is key. Here’s how I do it:

Adjust Voltage and Amperage Correctly

Setting your voltage and amperage too high can cause excessive heat input. I always refer to a welding chart to get the right starting point, then make fine adjustments based on the weld appearance.

Use the Right Travel Speed

A slower travel speed allows more heat to build up, while a faster speed reduces heat input. If you see excessive melting or burn-through, increase your travel speed.

Control Arc Length

A shorter arc length focuses heat more precisely, while a long arc length spreads heat out, increasing overall input. I always try to keep my arc length consistent to maintain even heat input.

Use Intermittent Welding

If too much heat is causing distortion, I sometimes weld in short bursts instead of continuous beads. This helps prevent overheating.

Allow Time for Cooling

If a part gets too hot, I stop and let it cool before continuing. I’ve found that allowing time for cooling reduces the risk of warping and cracking.

Industry Standards for Heat Input

Certain industries set limits on heat input to ensure weld quality and safety. For example:

- Structural welding (bridges, buildings) requires controlled heat input to prevent weak welds.

- Pipeline welding follows API 1104 standards, which include heat input limits.

- Aerospace welding has strict heat control requirements to prevent brittle welds.

In most cases, industry codes specify a minimum and maximum heat input range to ensure strong and durable welds.

Conclusion

Understanding heat input in welding is one of the most important skills for producing high-quality, defect-free welds. The amount of heat applied directly impacts penetration, distortion, cooling rate, and overall weld strength.

If you apply too much heat, you risk warping and weakening the metal. If you apply too little heat, you may get lack of fusion and weak welds. That’s why controlling voltage, amperage, and travel speed is crucial.

By learning how to calculate and adjust heat input, you can fine-tune your welding technique for stronger, cleaner, and more precise welds.

If you’re working on steel structures, pipelines, or automotive parts, mastering heat input will make you a better welder.

If you ever struggle with burn-through, cracks, or distortion, check your heat input settings—it might just be the key to fixing the problem.

FAQs

What is heat input in welding?

Heat input is the amount of energy transferred from the welding arc to the metal, affecting penetration, cooling rate, and weld strength.

How do you calculate heat input in welding?

Multiply voltage, current, and 60, then divide by travel speed in inches per minute. The result is in joules per inch.

Why is controlling heat input important?

Too much heat can cause distortion and weak welds, while too little heat can lead to lack of fusion and poor penetration.

Does travel speed affect heat input?

Yes. Slower travel speed increases heat input, while faster speed reduces it.

Which welding process has the highest heat input?

Submerged Arc Welding (SAW) generally has the highest heat input, while TIG welding (GTAW) has the lowest.