When I first started working with fillet welds, I quickly realized how important it was to understand their strength. Fillet welds are everywhere in welding—from structural beams to small metal brackets. Without the right calculations, it’s impossible to know if a weld can handle the load it’s designed for.

Image by red-d-arc

If you’ve ever wondered how to calculate fillet weld strength, you’re in the right place. I’ll break it down in simple terms so that anyone—whether you’re a beginner or an experienced welder—can understand and apply these calculations. Let’s get started.

Fillet Weld Strength

Fillet welds are used to join two metal pieces at an angle, typically 90 degrees. They are the most common type of weld in construction, manufacturing, and fabrication because they’re efficient, strong, and relatively easy to apply.

The strength of a fillet weld depends on three main factors:

- Size of the weld – The bigger the weld, the stronger it is.

- Length of the weld – A longer weld distributes the load better.

- Material strength – The strength of the base metal and the filler metal both play a role.

Knowing how to calculate these factors helps ensure your welds are strong enough for their intended purpose.

Basic Formula for Fillet Weld Strength

The shear strength of a fillet weld is typically calculated using this formula:

Fillet Weld Strength = Throat Size × Weld Length × Shear Strength of Weld Metal

Let’s break it down.

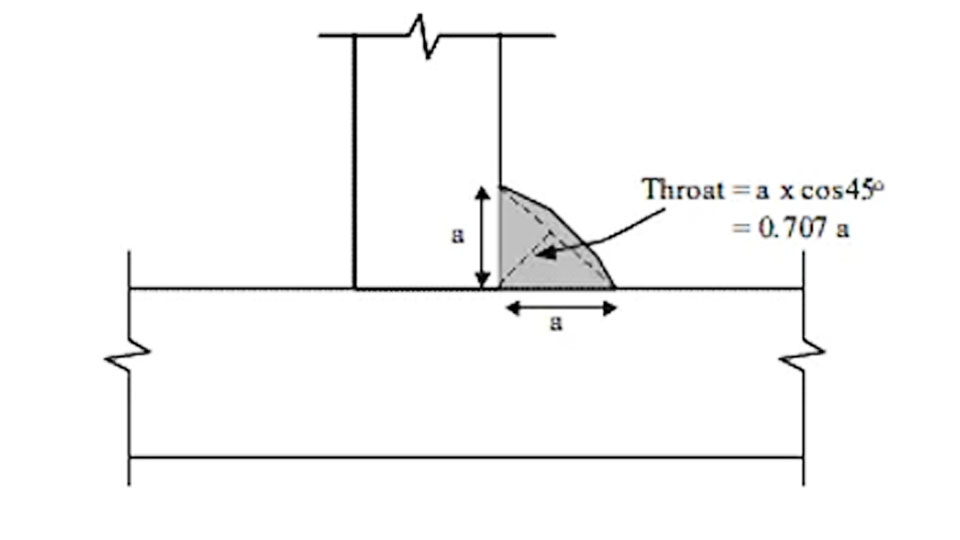

- Throat Size (T): This is the shortest distance from the root of the weld to the hypotenuse of the triangle formed by the weld.

- Weld Length (L): The total length of the weld along the joint.

- Shear Strength of Weld Metal (S): This is based on the filler material used, typically about 0.6 times the tensile strength of the weld metal.

Determining the Throat Size

The throat size is crucial in fillet weld calculations. It determines how much weld material is actively resisting shear forces. The formula for the effective throat size (T) is:

Throat Size (T) = 0.707 × Leg Size (Weld Size)

For example, if the leg size of the fillet weld is ¼ inch, the throat size is:

T = 0.707 × 0.25 = 0.177 inch

This value is then used in the strength calculation.

Example Calculation

Let’s say we have a 6-inch-long fillet weld on ¼-inch thick mild steel. The filler metal has a tensile strength of 60,000 psi, and the fillet weld size is ¼ inch.

- Determine the throat size:

T = 0.707 × 0.25 = 0.177 inch - Determine the shear strength of the weld metal:

Since the tensile strength of the filler metal is 60,000 psi, the shear strength is:

S = 0.6 × 60,000 = 36,000 psi - Calculate the weld strength:

Fillet Weld Strength = 0.177 × 6 × 36,000

= 38,052 pounds (or 38 kips)

This means the weld can withstand 38,052 pounds of shear force before failing.

Using a Table for Quick Reference

Here’s a table showing throat size values for different fillet weld sizes.

| Fillet Weld Size (in) | Throat Size (in) |

|---|---|

| 1/8″ | 0.088 |

| 3/16″ | 0.132 |

| 1/4″ | 0.177 |

| 5/16″ | 0.221 |

| 3/8″ | 0.265 |

| 1/2″ | 0.354 |

This table helps quickly determine throat size without needing to recalculate every time.

Factors That Affect Fillet Weld Strength

While calculations are important, real-world factors can impact weld strength. Here are some things to keep in mind:

Weld Quality

A properly welded joint will always be stronger than one with defects. Poor penetration, undercut, and porosity can weaken a fillet weld significantly.

Load Direction

Fillet welds handle shear forces well but are weaker in tension. If a weld will experience high tensile forces, reinforcing it with additional welds or a different joint design may be necessary.

Material Type

Different metals have different tensile and shear strengths. Always check the material specifications before performing calculations.

Welding Position

Welding in overhead or vertical positions may reduce the strength due to difficulty in achieving full penetration and proper fusion.

How to Ensure Strong Fillet Welds

Here are some tips to maximize the strength of your fillet welds:

- Use the correct weld size – An undersized weld can fail, while an oversized weld wastes material and can introduce stress concentrations.

- Ensure proper penetration – Lack of fusion can weaken the joint. Always make sure the weld fully bonds with the base metals.

- Control heat input – Too much heat can weaken the metal, while too little can lead to poor penetration.

- Use proper welding techniques – Good technique ensures a clean, strong weld with minimal defects.

Conclusion

Calculating fillet weld strength isn’t as complicated as it seems. By understanding throat size, weld length, and material strength, you can confidently determine whether your welds are strong enough for the job.

Fillet welds are widely used because of their efficiency and strength, but proper calculation and welding technique are essential for safe and reliable welds.

If you’re working on a small fabrication project or a large structural component, taking the time to get these calculations right will ensure your welds hold up under stress.

FAQs

What is the strongest type of weld?

A full penetration groove weld is generally stronger than a fillet weld because it fully joins the metal thickness.

How do I determine the correct fillet weld size?

The weld size is typically equal to or slightly smaller than the thickness of the thinner metal being joined.

What happens if my fillet weld is too small?

An undersized weld may not be able to handle the required load, leading to potential failure.

Why do we use 0.707 in fillet weld calculations?

The 0.707 factor comes from the geometry of a right triangle, as the throat of a fillet weld is the shortest distance across the weld triangle.

Understanding these calculations will help you create safe, strong, and efficient welds in all your projects!