Welding is the go-to method for joining metal, but sometimes it’s just not an option. Maybe you don’t have access to a welder, or you’re working on a project where heat could damage the material.

I’ve been in that situation plenty of times, and trust me—there are several effective ways to join metal rods without welding.

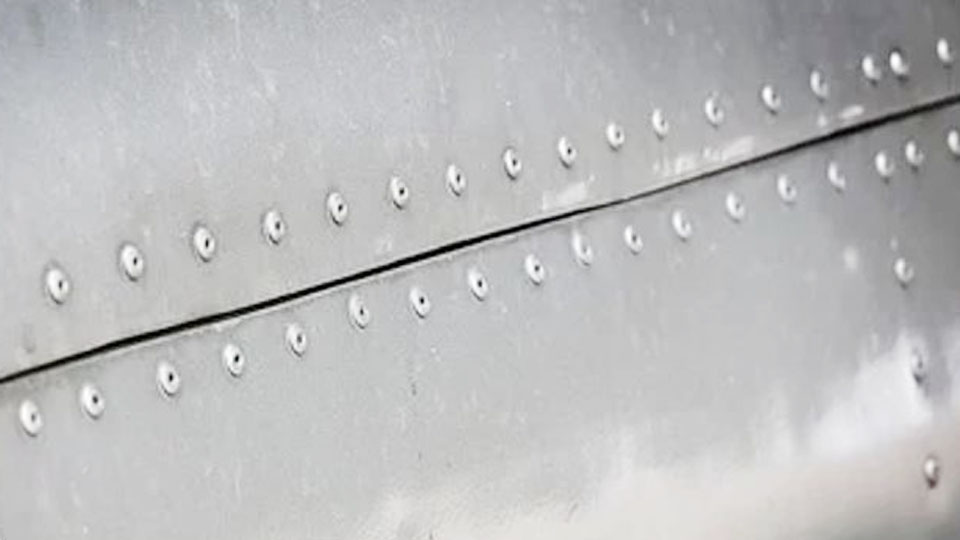

Photos forgeway

When I first started working with metal, I thought welding was the only way to make a strong connection. But after experimenting with different methods, I realized there are plenty of techniques that can hold metal rods together securely without ever striking an arc.

If you’re looking for reliable ways to join metal rods without welding, I’ll walk you through the best options, step by step. If you need a temporary fix or a permanent bond, there’s a method that will work for you.

Why Would You Need to Join Metal Rods Without Welding?

There are plenty of reasons you might want to avoid welding when joining metal rods:

- No access to welding equipment – Not everyone has a welder at home.

- Avoiding heat damage – Some metals can warp or weaken when exposed to high heat.

- Working on delicate or small projects – Welding might be too aggressive for certain applications.

- Quick repairs – You might need a fast and simple solution.

- Cost concerns – Welding requires expensive tools and materials.

Luckily, there are multiple ways to join metal rods without welding. Let’s go through the best methods.

Using Mechanical Fasteners

One of the simplest ways to join metal rods is by using mechanical fasteners like bolts, nuts, and screws. This method works well when you need a strong but removable connection.

Bolts and Nuts

This is one of the easiest and most reliable methods for joining metal rods.

How to do it:

- Drill a hole through both rods where you want the connection.

- Insert a bolt through the holes.

- Secure it with a nut and tighten it properly.

If you need extra strength, use lock washers or apply thread-locking adhesive to prevent loosening.

Threaded Rod Connectors

Threaded rod connectors, also called coupling nuts, are designed specifically for joining two rods.

How to use them:

- Make sure both rods are threaded at the ends.

- Screw both rods into the coupling nut.

- Tighten them securely for a strong hold.

This method works best for threaded metal rods and creates a permanent but adjustable connection.

Using Adhesives (Cold Welding)

If you need a seamless and clean connection, industrial adhesives can be a great option. Cold welding adhesives are designed to bond metal together without heat.

Epoxy Adhesives

Epoxy is a strong, durable adhesive that can bond metal rods securely.

How to use it:

- Clean the metal rods thoroughly to remove dirt, grease, and rust.

- Mix the two-part epoxy according to the instructions.

- Apply the adhesive to the joint and press the rods together.

- Clamp or hold the rods in place until the epoxy cures.

- Allow 24 hours for a full cure.

For extra strength, you can wrap the joint with metal wire or a sleeve while the epoxy cures.

Super Glue (Cyanoacrylate Adhesive)

Super glue works for small or lightweight metal rods, but it’s not as strong as epoxy. It’s best for quick fixes or temporary joins.

How to use it:

- Clean the surfaces and remove any oil or rust.

- Apply a small amount of super glue to one of the rods.

- Hold the pieces together for a few minutes.

- Let it cure completely before applying any stress.

While super glue is easy to use, it’s not suitable for heavy-duty applications.

Brazing and Soldering

Brazing and soldering are low-heat alternatives to welding that can create strong metal bonds without melting the base material.

Brazing

Brazing is similar to welding, but it uses a filler metal with a lower melting point. This method creates a strong, permanent joint.

How to braze metal rods:

- Clean the metal rods to remove any dirt or rust.

- Apply a flux to the joint area (this helps the filler metal flow smoothly).

- Use a torch to heat the rods to the filler metal’s melting temperature.

- Apply the brazing rod to the joint, allowing it to flow between the metal pieces.

- Let it cool completely before handling.

Brazing provides a solid and heat-resistant joint, making it a great alternative to welding.

Soldering

Soldering is similar to brazing but uses even lower temperatures. This method works best for thin metal rods or electrical connections.

How to solder metal rods:

- Clean the rods and apply soldering flux.

- Heat the joint with a soldering iron or torch.

- Apply solder wire until it melts and fills the joint.

- Let it cool completely before testing the bond.

Soldering isn’t as strong as brazing, but it’s good for low-stress applications.

Clamping and Compression Fittings

If you want a strong but removable connection, clamping and compression fittings are a great option.

Hose Clamps or Pipe Clamps

These work well for temporary or adjustable joints.

How to use them:

- Place the rods side by side or overlapping.

- Wrap a hose clamp or pipe clamp around the joint.

- Tighten the clamp until the rods are secure.

This method works well for temporary fixes or adjustable connections.

Compression Fittings

Compression fittings are metal sleeves that create a tight grip between two rods.

How to use them:

- Insert the rods into the compression fitting.

- Tighten the fitting using a wrench.

- The sleeve compresses onto the rods, creating a solid hold.

This method is often used in plumbing and structural applications.

Wrapping with Wire or Metal Bands

If you need a quick and easy way to hold two rods together, wrapping them with wire or metal bands can do the trick.

Wire Wrapping

Using steel wire to bind the rods together can create a secure joint.

How to do it:

- Wrap the rods tightly with strong wire.

- Use pliers to twist the wire and secure the joint.

- Apply epoxy or solder over the wire for extra strength.

Metal Bands or Straps

Metal bands can be wrapped around the rods and secured with bolts or clamps.

This method is great for structural applications where you need a strong, load-bearing joint.

Conclusion

As you can see, welding isn’t the only way to join two metal rods. Depending on your needs, you can use bolts, adhesives, brazing, clamps, or wire to create a strong and reliable connection.

If you need a permanent bond, brazing or epoxy is a great choice. For a removable connection, bolts, clamps, or compression fittings work well.

No matter what method you choose, the key is to prepare the metal properly and select the right technique for your specific project.

Next time you need to join two metal rods and don’t have a welder, you’ll have plenty of options to get the job done right!

FAQs

What is the strongest way to join metal without welding?

Brazing and epoxy adhesives provide the strongest bond without welding.

Can I use glue to join metal rods?

Yes, industrial epoxies and cold welding adhesives work well for bonding metal.

Is brazing as strong as welding?

Brazing creates a strong joint, but it’s not as strong as a full-penetration weld.

How do I remove a joint if I need to?

If you used bolts, clamps, or compression fittings, you can easily disassemble the connection.

With the right approach, you can securely join metal rods without ever striking an arc!