I’ve worked on enough plumbing projects to know that soldering isn’t always the best option when joining copper pipes. Sometimes, you don’t have a torch on hand, or you’re working in a tight space where using an open flame is risky.

Maybe you just prefer a cleaner, easier method. The good news? You can absolutely join copper pipes without soldering, and there are multiple ways to do it.

Image by instructables

If you’re fixing a leak, installing a new water line, or tackling a DIY plumbing project, you don’t have to be a professional plumber to get the job done.

Let me walk you through the best solder-free methods for joining copper pipes, along with tips to make sure your connections are strong and leak-proof.

Why Avoid Soldering?

Soldering is the traditional way to join copper pipes, but it comes with some downsides:

- Fire hazard – Using a torch in tight spaces can be dangerous, especially near wood, insulation, or gas lines.

- Skill required – A proper soldered joint takes practice. If done incorrectly, it can lead to leaks.

- Time-consuming – You have to clean, flux, heat, and apply solder carefully, which takes more effort than some modern alternatives.

- Not always practical – If water is present inside the pipe, soldering won’t work properly, making it tough for repairs.

Luckily, there are several alternative methods that are just as reliable—some even easier than soldering.

Best Ways to Join Copper Pipes Without Soldering

There are four main ways to join copper pipes without solder:

- Push-to-Connect (SharkBite) Fittings

- Compression Fittings

- ProPress (Press Fittings)

- Epoxy or Pipe Adhesives

Each of these methods has its pros and cons, so let’s go through them one by one.

Push-to-Connect (SharkBite) Fittings

If you want the easiest, fastest way to connect copper pipes, push-to-connect fittings are the way to go. These fittings—commonly known as SharkBite fittings—use a rubber O-ring and metal teeth to grip the pipe and create a watertight seal.

How to Use Push-to-Connect Fittings

- Cut the Pipe Cleanly – Use a pipe cutter to make a straight, burr-free cut.

- Deburr and Clean the Pipe – Smooth the edges so they don’t damage the fitting’s O-ring.

- Push the Fitting On – Insert the pipe into the fitting until it locks into place.

- Check the Connection – Give it a slight tug to ensure it’s secure.

Pros and Cons of Push-to-Connect Fittings

| Pros | Cons |

|---|---|

| Quick and easy—no tools or heat required | More expensive than other options |

| Works on both wet and dry pipes | Bulkier than traditional soldered joints |

| Can be removed and reused | Not ideal for permanent, high-pressure applications |

Best for: DIYers, quick repairs, and small plumbing projects where speed and simplicity matter.

Compression Fittings

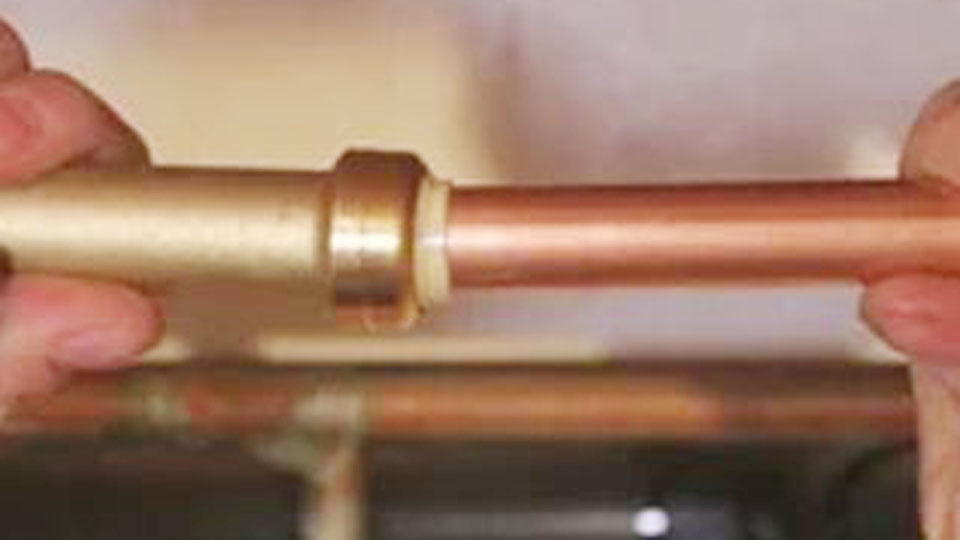

Compression fittings use a brass ring (ferrule) that gets compressed between the pipe and the fitting when tightened. They create a strong, reliable seal without needing heat or special tools.

How to Use Compression Fittings

- Slide the Nut and Ferrule Onto the Pipe – First, put the compression nut onto the pipe, followed by the ferrule.

- Insert the Pipe into the Fitting – Push the pipe into the body of the fitting.

- Tighten the Nut – Use two wrenches to tighten the nut until it compresses the ferrule against the pipe.

- Check for Leaks – Turn on the water and inspect the connection.

Pros and Cons of Compression Fittings

| Pros | Cons |

|---|---|

| Strong, long-lasting connection | Takes longer to install than push-to-connect fittings |

| No fire hazard or heat required | Can’t be reused once tightened |

| Works well for high-pressure water lines | Slightly more skill needed for a leak-proof seal |

Best for: Permanent installations, under-sink connections, and plumbing projects where a secure, non-removable connection is needed.

ProPress (Press Fittings)

ProPress is a professional-grade system that uses a special press tool to crimp fittings onto copper pipes. It creates a permanent, watertight seal that’s just as strong as soldering.

How to Use ProPress Fittings

- Cut and Deburr the Pipe – Make sure the pipe end is smooth and clean.

- Insert the Pipe into the Press Fitting – The fitting has an integrated sealing ring inside.

- Use the Press Tool – A hydraulic press tool crimps the fitting in place, creating a secure joint.

- Check the Connection – Turn on the water and inspect for leaks.

Pros and Cons of ProPress Fittings

| Pros | Cons |

|---|---|

| Permanent, leak-proof connections | Requires a special press tool (expensive) |

| Works on wet pipes | Not DIY-friendly due to tool cost |

| Faster than soldering for large projects | Less common for small home repairs |

Best for: Professionals, large plumbing projects, and anyone who needs a strong, permanent alternative to soldering.

Epoxy or Pipe Adhesives

If you’re in a pinch, epoxy-based adhesives or pipe joint compounds can be used to join copper pipes. These work by chemically bonding the metal surfaces together.

How to Use Epoxy for Copper Pipes

- Clean the Pipe Ends – Remove oxidation and dirt for better adhesion.

- Apply the Epoxy – Spread the adhesive evenly on both pipe ends.

- Join the Pipes – Press them together and hold them in place.

- Let It Cure – Follow the manufacturer’s instructions for drying time.

Pros and Cons of Epoxy Adhesives

| Pros | Cons |

|---|---|

| No tools or special fittings required | Not as strong as mechanical connections |

| Works in tight spaces | Takes time to cure |

| Can be used on small repairs | May not hold up under high pressure |

Best for: Temporary fixes, low-pressure applications, or areas where mechanical fittings won’t fit.

Which Method Should You Choose?

If you’re unsure which option to go with, here’s a quick guide:

- For the easiest, fastest method → Use push-to-connect fittings (SharkBite)

- For a more permanent, strong connection → Use compression fittings

- For professional, high-pressure plumbing → Use ProPress fittings

- For small repairs or emergencies → Use epoxy adhesives

Conclusion

Soldering isn’t the only way to join copper pipes. Whether you need a quick fix or a permanent solution, there are plenty of solder-free options to choose from. Push-to-connect fittings are great for beginners, while compression fittings and ProPress are better for long-term projects. If you’re in a pinch, epoxy adhesives can also work for small repairs.

No matter which method you choose, make sure your pipe cuts are clean, connections are tight, and you test for leaks before finishing your project. Plumbing doesn’t have to be difficult, and with these options, you can get the job done without ever picking up a torch.

Frequently Asked Questions

Can I use push-to-connect fittings for permanent plumbing?

Yes, but they’re best for repairs and small projects. For long-term reliability, compression or ProPress fittings are better.

Are compression fittings stronger than SharkBite fittings?

Yes, compression fittings create a tighter seal and are less likely to fail over time.

How long does epoxy take to cure?

It depends on the brand, but most take several hours to fully harden.

Do ProPress fittings require maintenance?

No, once crimped, they form a permanent, leak-proof connection.

Avoiding soldering doesn’t mean sacrificing quality. With the right method, you can create strong, leak-free copper pipe connections—no torch required!