Working with cast iron can be a challenge, especially when it comes to repairing cracks or broken parts. Unlike steel or aluminum, cast iron is brittle and doesn’t handle heat well. That’s why cold welding is one of the best methods to repair cast iron without risking further damage.

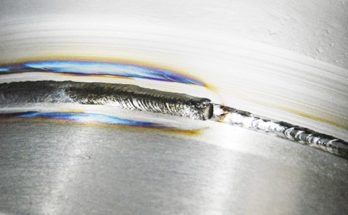

Image by millerwelds

I’ve worked with cast iron repairs on engine blocks, machinery, and antique parts, and I know how tricky it can be. Traditional welding methods can easily cause cracks due to thermal stress. But cold welding, when done correctly, provides a strong, lasting repair without excessive heat.

I’ll walk you through everything you need to know about cold welding cast iron, from preparation to the best techniques and materials to use. Whether you’re fixing an old cast iron stove or repairing a cracked engine block, this guide will help you get the job done right.

What Is Cold Welding?

Cold welding is a process that joins metal without using heat. Instead, pressure and a special adhesive or filler material create a strong bond between the broken pieces. This method is ideal for cast iron because it avoids the thermal expansion and contraction that often causes cracks in traditional welding.

Cold welding can be done using:

- Metal-filled epoxy adhesives – These create a bond between the broken pieces.

- Specialized cold welding rods – Used for a low-heat welding approach.

- Mechanical fastening with stitching pins – A non-welded way to secure the broken parts.

This method is widely used in automotive repairs, plumbing, and industrial applications where heating cast iron would be risky.

Why Choose Cold Welding for Cast Iron?

Cast iron is tricky to weld because of its high carbon content. When heated, it becomes brittle and prone to cracking. Cold welding is a great alternative because it:

- Avoids thermal stress – No extreme heat means no risk of further cracking.

- Works on thin and thick sections – Unlike traditional welding, it can be used on delicate or large parts.

- Requires minimal equipment – No expensive welding machine needed.

- Can be done at home – Many cold welding methods can be performed without professional tools.

How to Cold Weld Cast Iron

If you want to cold weld cast iron successfully, preparation is key. Follow these steps to ensure a strong, lasting repair.

Step 1: Clean the Surface

Before applying any cold welding material, the surface must be free from dirt, oil, rust, and old paint.

- Use a wire brush or sandpaper to remove debris.

- Wipe down the area with acetone or degreaser.

- Ensure the surfaces fit together well before proceeding.

Step 2: Choose the Right Cold Welding Method

There are three main approaches to cold welding cast iron. Each has its advantages, depending on the size of the repair and the tools available.

| Cold Welding Method | Best For | Materials Needed |

|---|---|---|

| Metal-filled epoxy | Small cracks, minor breaks | Epoxy, mixing tools, clamps |

| Cold welding rods | Larger repairs, structural fixes | Low-heat welding rods, torch |

| Metal stitching | Engine blocks, pressure pipes | Stitching pins, drill, hammer |

Step 3: Apply Metal-Filled Epoxy (For Small Repairs)

For minor cracks or non-structural parts, metal-filled epoxy is the easiest solution.

- Mix the epoxy as directed on the packaging.

- Apply a thin, even layer over the broken surfaces.

- Press the pieces together and secure with clamps or tape.

- Allow it to cure fully (usually 24 hours) before using the part.

This method works well for cast iron stoves, pipes, and decorative items that don’t undergo extreme stress.

Step 4: Use Cold Welding Rods (For Larger Repairs)

If you need a stronger bond, cold welding rods are the way to go. These are special low-heat welding rods designed for cast iron.

- Heat the rod slightly with a torch to activate the bonding material.

- Apply the rod in short sections, avoiding too much heat buildup.

- Let the joint cool naturally—do not quench with water.

This method provides a strong repair without excessive heat, making it suitable for machine parts and automotive repairs.

Step 5: Metal Stitching (For High-Stress Repairs)

When dealing with large cracks in engine blocks or heavy-duty machinery, metal stitching is the best approach.

- Drill small holes along the crack’s length.

- Insert and hammer stitching pins into the holes.

- Grind down the surface for a smooth finish.

This method distributes stress evenly across the crack, making it a reliable solution for high-pressure applications.

Tips for a Successful Cold Weld on Cast Iron

- Take your time – Rushing the process can lead to weak bonds.

- Use high-quality materials – Cheap epoxies or rods won’t hold up.

- Prepare the surface properly – Dirt and oil can weaken the bond.

- Allow full curing time – Epoxy and cold weld rods need time to reach full strength.

Common Mistakes to Avoid

Many people make simple mistakes when trying to cold weld cast iron. Here’s what to watch out for:

| Mistake | Problem It Causes | How to Fix It |

|---|---|---|

| Not cleaning the surface | Weak bond | Clean with acetone and sandpaper |

| Using too much heat | Can cause new cracks | Keep the temperature low |

| Not clamping properly | Misalignment or weak joint | Use clamps or weights |

| Rushing the cure time | Bond won’t reach full strength | Wait at least 24 hours |

When to Use Cold Welding vs Traditional Welding

Cold welding is great for crack repairs, delicate parts, and quick fixes, but it may not be ideal for every situation. If you need a structural repair on a load-bearing part, traditional welding might be necessary.

Choose cold welding when:

- The part cannot handle heat (engine blocks, old cast iron items).

- You need a quick, non-invasive repair.

- You’re working on thin or brittle cast iron.

Use traditional welding when:

- The part needs extreme durability.

- You have experience with cast iron welding.

- The break is in a high-stress area.

Conclusion

Cold welding is a fantastic way to repair cast iron without the risks of overheating and cracking. Whether you’re using metal-filled epoxy, cold welding rods, or metal stitching, each method has its place depending on the type of repair you need.

I’ve used cold welding on everything from cracked engine blocks to antique cast iron cookware, and it’s proven to be a reliable solution. The key to success is proper surface preparation, choosing the right method, and allowing the materials to fully cure.

If you take your time and follow the right steps, cold welding can save you money and keep your cast iron parts working for years to come.

FAQs

Can I cold weld a cracked engine block?

Yes, using metal stitching or high-strength epoxy can repair engine block cracks.

How strong is cold welding on cast iron?

Cold welding is very strong when done correctly, but it’s best for non-load-bearing repairs.

Does cold welding require special tools?

No, most methods only require basic tools like a wire brush, clamps, and epoxy or welding rods.

Can I cold weld cast iron without cleaning it first?

No, surface preparation is critical for a strong bond. Always clean the area before welding.

Is cold welding waterproof?

Yes, once fully cured, epoxy-based cold welds are waterproof and resistant to corrosion.