If you’ve ever tried working with bronze and wondered how to weld it properly, I’ve got you covered. I’ve spent a lot of time experimenting, failing, and finally learning the best ways to TIG weld bronze. It’s not as tricky as it first seems, but it does take a careful approach.

I’m going to walk you through everything you need to know about TIG welding bronze—from materials and prep to technique and post-weld care.

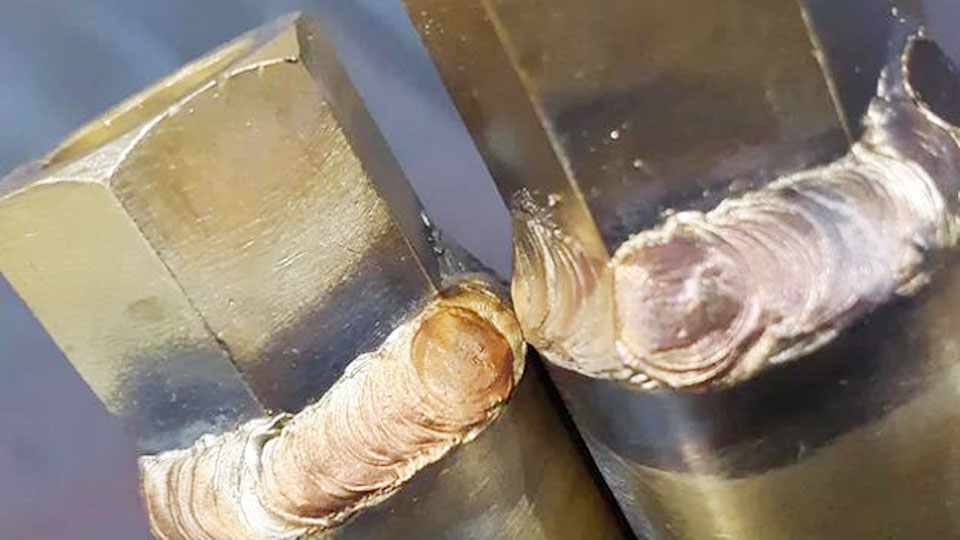

Image by reddit

This guide is perfect if you’re a beginner or someone with experience in welding but haven’t yet worked with bronze.

I’ll explain everything in the simplest way possible, like we’re just two folks sitting in a garage workshop chatting about welding.

What Is Bronze and Why Is It Welded?

Bronze is a metal alloy primarily made from copper and tin. Sometimes, it includes other elements like aluminum, phosphorus, or silicon. It’s known for its strength, corrosion resistance, and attractive appearance.

People choose to weld bronze for various reasons—artwork, sculptures, marine hardware, bushings, or repairing bronze components.

TIG welding is a great choice because it gives you precision and clean welds without making a mess of the base metal.

Why Use TIG Welding for Bronze?

Now, you might be asking, “Why TIG welding and not MIG or stick?” Well, here’s the deal—TIG (Tungsten Inert Gas) welding gives you better control over the heat and the filler metal. That’s important because bronze is sensitive to heat and can become porous or crack if overheated.

TIG also produces cleaner welds, which is perfect if you’re welding something decorative or structurally sensitive.

With TIG, you use a tungsten electrode that doesn’t melt, and you add filler metal manually. This helps you guide the process with more finesse.

Choosing the Right Type of Bronze for TIG Welding

Before striking an arc, it’s important to understand what type of bronze you’re working with. Not all bronzes behave the same. Here’s a quick breakdown:

| Type of Bronze | Common Name | Key Features |

|---|---|---|

| Phosphor Bronze | Copper + Tin + Phosphorus | Good strength, corrosion resistance |

| Silicon Bronze | Copper + Silicon | Easy to weld, used often in TIG welding |

| Aluminum Bronze | Copper + Aluminum | High strength, corrosion resistant |

| Manganese Bronze | Copper + Zinc + Manganese | High tensile strength, can be tricky to weld |

For TIG welding, Silicon Bronze is the most commonly used. It flows nicely, handles heat well, and gives a smooth finish.

Tools and Materials You’ll Need

Here’s a quick list of what you need to get started:

- TIG welder (AC/DC depending on the bronze alloy)

- 2% Thoriated or Lanthanated tungsten electrode (3/32” is usually good)

- Argon shielding gas (100% pure)

- Filler rod (often ERCuSi-A for Silicon Bronze)

- Bronze base metal (clean and dry)

- Copper or bronze brush (for cleaning)

- Angle grinder or wire wheel (optional)

- Protective gear (helmet, gloves, jacket, etc.)

You don’t need fancy tools. But you do need to use clean equipment. Bronze can be fussy about contamination, so make sure everything you use is free of grease, oil, or dust.

Surface Preparation Is Critical

This step is often rushed, but it shouldn’t be. Bronze picks up oxides and grime quickly, and that can mess up your weld.

Start by scrubbing the area you want to weld using a stainless steel brush or a dedicated bronze brush. Don’t use the same brush you used on steel or aluminum. That’ll contaminate the surface.

If the bronze piece is greasy or has oil on it, wipe it down with acetone or a degreaser. Also, make sure your filler rod is clean too. Any dirt or oxidation can cause porosity in the weld.

Setting Up the TIG Welder for Bronze

TIG welding bronze isn’t like welding mild steel or aluminum. The settings depend a bit on the type of bronze alloy you have. But here’s a general guideline that works well with silicon bronze:

- Polarity: DCEN (Direct Current Electrode Negative)

- Amperage: Start around 70–90 amps (adjust as needed)

- Gas Flow: Around 15–20 CFH of pure Argon

- Tungsten: 2% Thoriated or Lanthanated, sharpened to a point

- Filler Rod: ERCuSi-A for most bronze types

If you’re using aluminum bronze, you might need more amperage or preheat the metal slightly.

Preheating May Be Necessary

Bronze, especially thicker sections or aluminum bronze, tends to crack if it’s welded cold. If you notice cracking or brittleness, preheat the base metal to about 300°F (150°C). A propane torch works fine for this.

Don’t overdo it though—too much heat can cause the bronze to warp or get porous. Use a temp stick or infrared thermometer if you have one.

Technique for TIG Welding Bronze

Here comes the hands-on part. Once your metal is clean and your welder is set, here’s what you do:

Tack Weld First

Place small tack welds at key points to hold the bronze in position. This helps with heat distribution and avoids warping.

Start Your Arc Smoothly

Begin the arc with the torch slightly tilted (about 10–15 degrees). Hold the tungsten just above the bronze, then activate your foot pedal gently.

Form a Molten Pool

Once a puddle forms, feed your filler rod into the leading edge of the puddle. Keep your filler rod in the gas shield at all times.

Use Small Circles or Weave Lightly

You can either use a tight circular motion or lightly weave depending on the joint type. Bronze likes slower, smoother movements.

Watch the Color

Bronze will turn a golden, shiny color when it’s hot enough. If it starts getting reddish or dull, ease off the heat.

Let It Cool Slowly

Don’t dunk it in water. Let the bronze air-cool naturally to avoid cracking.

Common Problems and How to Fix Them

Here are a few things that might happen and how to handle them:

| Problem | Why It Happens | What to Do |

|---|---|---|

| Cracking | Metal too cold or moved too quickly | Preheat the base metal, slow down |

| Porosity (bubbles) | Contamination or poor gas coverage | Clean the metal, increase argon flow |

| Weak welds | Wrong filler rod or poor fusion | Use correct filler, adjust amperage |

| Oxidation (dark spots) | Gas flow issue or drafty work area | Check torch angle, increase gas coverage |

Post-Weld Cleaning and Finishing

Once your weld is done, give it a good visual inspection. Bronze welds should be smooth and golden in color.

Use a bronze wire brush or buffing wheel to clean off any residue. If you want a polished finish, you can sand it lightly and buff with a polishing compound.

For marine or outdoor bronze parts, consider applying a light protective coating to prevent oxidation.

Practice Makes Perfect

If it doesn’t go right the first time, don’t worry. Bronze has a learning curve. I ruined quite a few test pieces before I nailed it. Try practicing on some scrap bronze pieces before working on your actual project. Play with the heat and speed until you find the sweet spot.

When Should You Not TIG Weld Bronze?

There are a few times when TIG welding might not be the best method. For example, if the bronze is very thick or heavily contaminated, TIG might struggle to penetrate deep enough.

If you’re working in a windy environment without a good shielding setup, your argon gas might not do its job, and the weld could turn out messy.

In those cases, you might consider brazing or stick welding with a specialized bronze electrode.

Final Thoughts on TIG Welding Bronze

TIG welding bronze isn’t as intimidating as it sounds once you break it down step by step. The key is in the prep, patience, and using the right settings and filler. It’s a satisfying metal to work with once you get the hang of it.

The color, texture, and feel of bronze make it one of my favorite materials. Whether you’re repairing a bronze part or creating something entirely new, using TIG welding gives you the control and beauty that this metal deserves.

Take your time, don’t rush the process, and most importantly—enjoy it. Welding bronze can be both functional and artistic, and with TIG, you get the best of both worlds.

FAQs

What filler rod should I use for TIG welding bronze?

You should use ERCuSi-A filler rod, which is silicon bronze. It matches well and flows smoothly when TIG welding.

Do I need to preheat bronze before TIG welding?

For thin sections, preheating may not be necessary. But for thicker or aluminum bronze, preheating to around 300°F helps avoid cracking.

Can I TIG weld bronze to steel?

Yes, you can join bronze to steel using TIG welding, especially with silicon bronze filler. But remember, it’s more like brazing, and the joint won’t be as strong as steel-to-steel.

Why is my bronze weld full of bubbles?

That’s likely due to contamination. Make sure the base metal and filler rod are clean and that your shielding gas is flowing properly.

What’s the best shielding gas for TIG welding bronze?

Use 100% pure Argon gas. It provides a clean arc and protects the weld from oxidation.

Can beginners TIG weld bronze?

Absolutely. It just takes a little practice. Start with silicon bronze, clean your metal well, and go slow. You’ll get the hang of it quickly.